In-Situ Replication Metallography and Replica Testing

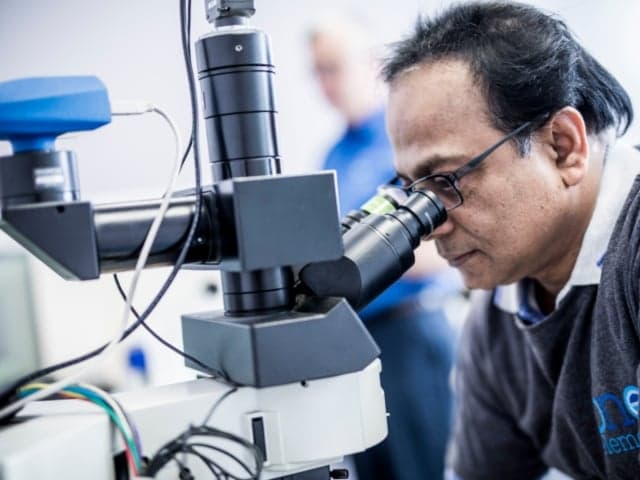

Element's non-destructive in-situ replication metallography and replica testing services help you determine material strength, quality, and remaining lifetime without disrupting operations. Our accredited laboratories and experienced metallurgists combine advanced testing methods to detect potential failures early, ensuring safe, compliant operations in your high-temperature petrochemical and refinery equipment.

What is In-situ Replication Metallography and Replica Testing at Element?

Replication metallography is a non-destructive sampling procedure which records and preserves the topography of a metallographic specimen as a negative relief on a plastic film. The microstructural replica can be examined using a light microscope or Scanning Electron Microscope (SEM) for subsequent analysis.

The replicas may pick up loose particles or residue from the surface, which may be used for Energy Dispersive X-Ray Spectroscopy (EDS) analysis.

Element combines a diversity of advanced metallographic equipment and tools with a dedicated team of experienced metallurgists to conduct high quality of all replica examinations and deliver accurate, reliable results you can trust.

What can Element offer you for Replication Metallography Testing?

Key tests offered

Key tests offered

As one of the largest independent providers of non-destructive testing (NDT) services, Element offers unrivaled experience and expertise in in-situ replication metallography to perform and analyze replica tests for obtaining microstructures on-site, for subsequent examination and evaluation in our fully accredited laboratories.

Replica testing procedures and techniques

- Selection of location

- Visual inspection

- Surface and specimen preparation (metallographic grinding, polishing and etching)

- Microstructure examination

- Replication

- Examination of replica

In-situ replication metallography and replica examination services

- Microstructure evaluation

- Creep damage assessment – mostly on high-pressure and high-temperature equipment such as steamlines, boilers and reactors.

- Thermal degradation of the materials – mostly on stainless steels in high-temperature equipment, where detrimental precipitation and the Degree of Sensitization (DOS) can be assessed. Thermal degradation can also occur during unwanted high-temperature exposure, such as fire damage or hot spots.

- Failure analysis/crack analysis

- Graphitization

Components and materials we test

Components and materials we test

We specialize in testing high-pressure and high-temperature equipment across petrochemical, refinery, and oil & gas industries. Our expertise covers a wide range of metals and alloys, including austenitic stainless steels, nickel and chromium based alloys, carbon steel, low alloy steel, and duplex stainless steel. We focus particularly on critical components like steamlines, boilers, and reactors where material integrity is paramount.

Methods and solutions offered

Methods and solutions offered

Our metallurgists are highly skilled in the preparation of the replicas using a number of techniques and can advise you in choosing the appropriate method for your specific project needs.

From on-site evaluation of a component’s metallurgical and heat treatment condition to conducting a remaining life assessment study and a failure analysis project, our skilled teams of metallurgists can verify the on-site, non-destructive microstructure of any given component.

Combine your testing

Our experts combine tests to get the most complete indication of the examined equipment; for instance, to determine whether a material has been thermally degraded, the replica tests are combined with hardness measurements. If microstructure examination is not sufficient on the surface alone, our metallurgists can take boat samples for examinations on (partial) cross-sections.

Labs that offer this service

Labs that offer this service

Our team operates from energy testing hubs across the world, providing global access to our expert capabilities. Find out where your nearest energy testing hub is on our Locations Page.

Standards we test to and materials we test

We follow the guidelines in ASTM 1315, ASTM E3, ASTM E340 and ASTM E407 to identify, prepare and examine in-situ metallographic replicas.

With over 20 years of experience in Petrochemical, Refinery, Industrials and Oil and Gas industries, we can perform replica tests on a wide range of metals and alloys such as austenitic stainless steels, nickel and chromium based alloys, carbon steel, low alloy steel, and duplex stainless steel.

Your Challenges, Our Solutions

Prevent Catastrophic Equipment Failure

Need Testing Without Production Disruption

High-Temperature Equipment Deterioration Risk

Complex Material Degradation Assessment

Why Choose Element

Industry Leader in NDT

Comprehensive Analysis Capabilities

Trusted Quality Standards

Wide Material Expertise

20+years

23global energy labs

600+scientists & engineers

17025accreditation

Speak to our team of experts

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Metallurgical Testing Services

Expert metallurgical testing services to verify material integrity and prevent failures. Our accredited laboratories deliver precise analysis of metal microstructures, properties, and defects with expedited options. Ensure product reliability and compliance with industry standards.

Failure Analysis Services

Need expert Failure Analysis Services? Identify root causes fast with Element's advanced testing, global reach, and rapid turnaround. Get expert insights today.

On-Site Metallographic Testing and Analysis

Element's on-site metallographic testing provides non-destructive analysis to assess material condition, detect defects early, and support informed decision-making in aerospace, oil & gas, and industrial applications.

Stress Rupture and Creep Testing

Element provides stress rupture and creep testing to evaluate material durability under prolonged stress and temperature. Our expert analysis supports manufacturers in preventing failures and ensuring long-term product performance.