Contaminant Analysis and Complaints Investigations

Fast-track your regulatory compliance and protect product quality with comprehensive pharmaceutical contaminant testing and biopharmaceutical contaminant analysis. From immediate FDA-mandated investigations to preventive quality control, we help you identify and prevent contamination issues while maintaining compliance and minimizing production disruptions. Our expert team delivers rapid results with collaborative support throughout your investigation process.

What is Contaminant Analysis and Complaints Investigations Testing at Element?

Contaminant analysis and complaints investigation involves identifying unknown particles, impurities, and their sources in pharmaceutical and consumer products. At Element, we provide comprehensive contamination detection investigation services, from rapid isolation and identification of contaminants to thorough analysis of their sources, supported by preventive measures to protect your product quality and compliance.

What Can Element Offer You For Contaminant Analysis and Complaints Investigations?

Components And Products We Test

Components And Products We Test

From raw materials to finished products, we analyze every component in your production chain. Our comprehensive testing covers manufacturing equipment, packaging materials, processing aids, and final products, monitoring for contamination at every stage. We specialize in identifying foreign particles, precipitates, and impurities across diverse material types.

Key Tests Offered

Key Tests Offered

- Contaminant isolation and identification

- Particulate analysis and characterization

- Glass delamination testing to USP <1660>

- Injectable drug products testing to USP <788>, Ph.Eur./EP 2.9.19, JP 6.07

- Biologics testing to USP <787>

- Elemental impurities testing to ICH Q3D, USP <232>, USP <233>

- Impurity testing to ICH Q3A, ICH Q3B, USP <1086>, USP <476>

Biopharmaceutical and pharmaceutical contaminant testing services:

- Glass Delamination in Pharmaceutical Containers

Glass delamination in parenteral vials is a significant concern in the biopharmaceutical industry, as glass particles in drug products can lead to recalls. Element offers expertise in vial delamination testing, meeting USP <1660> standards for glass delamination screening.

- Identification and Characterization of Particulates

Our expert scientists specialize in identifying and characterizing particulates, including their shape, morphology, and color. We test injectable drug products to USP <788>, Ph.Eur./EP 2.9.19, and JP 6.07, as well as biologics to USP <787>.

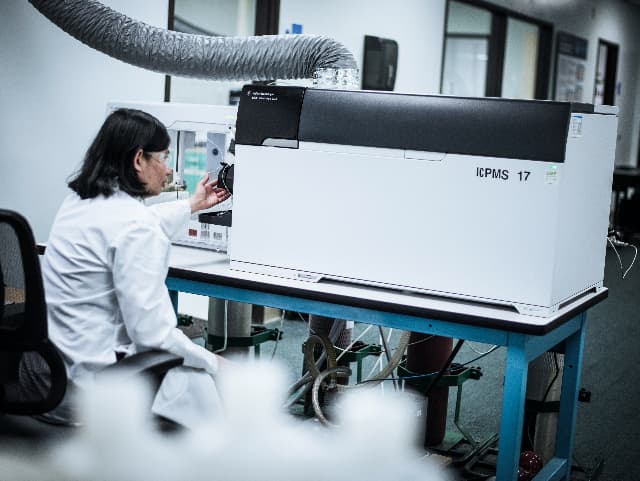

- Elemental Profiling of Particulates

Element’s comprehensive trace metal testing and analysis services include metals speciation, elemental impurities testing to ICH Q3D, USP <232>, and USP <233>, and customized multi-element analyses for heavy metals and trace elements.

- Isolation, Characterization, and Identification of Precipitates

Our experienced scientists analyze pharmaceutical solutions to isolate, identify, and characterize precipitates, distinguishing immiscible phases from solids.

- Contaminant Particle Size and Count

Particle size and count analysis is crucial when investigating multiple particle types in pharmaceutical products. Element provides contaminant and particulate analysis, including particle count, size, and distribution.

- Identification of Foreign Matter

Element has extensive experience in analyzing various materials and conducting forensic investigations within the pharmaceutical industry.

- Residue, Stain, and Discoloration Analysis

We can isolate and identify stains, discoloration, and residue, even with minimal sample amounts available for testing.

- Impurity Identification

Element offers comprehensive impurity testing solutions, including testing to ICH Q3A, ICH Q3B, USP <1086>, and USP <476>.

- Extractables and Leachables (E&L) Studies

With one of the largest and most experienced E&L teams in the world, Element’s in-depth knowledge of regulatory guidelines and advanced equipment provides the foundation for our industry-leading E&L services.

Consumer Product and Specialty Chemical Contaminant Testing:

Manufacturers must conduct thorough testing of both raw materials and finished products to ensure consistency, safety, and efficacy, including checking for contaminants. This includes testing consumer products for harmful substances and assessing packaging materials like glass, rubber, aluminium, plastic, and paper, which may also contribute to contamination. Our expert team quickly and accurately identifies the source of any foreign particulate matter using a stepwise approach.

Element’s analytical scientists leverage their material science expertise and advanced instrumentation to detect, isolate, and identify contaminants, precipitates, and unknown impurities. Our consultative team works alongside your staff to identify potential contamination sources in raw materials and finished products. To prevent future contamination, we offer quality control services like batch-to-batch testing, refined product development, and raw material analysis. Contact an expert today to explore Element’s contaminant analysis services.

Biopharmaceutical and Pharmaceutical Contaminant Testing:

The FDA requires thorough investigation of contaminants in pharmaceutical products and process streams. Manufacturers must test materials, processes, equipment, techniques, environments, and personnel to ensure product safety and efficacy. Element’s comprehensive testing services identify the source of foreign particulate matter in biologics and pharmaceutical products, supporting OOS investigations, product failures, and quality control issues.

Our experts detect, isolate, and identify contaminants, precipitates, and unknown impurities down to trace levels. We work with your team to find potential contamination sources, including raw materials, processing aids, and packaging lines. Prevent future contamination risks with our quality control checks, batch-to-batch testing, product development methods, and raw material testing.

Methods And Solutions Offered

Methods And Solutions Offered

We tailor our approach to your specific needs, offering both standardized and custom testing methods. Our wraparound services include:

- Batch-to-batch testing programs

- Process revalidation studies

- Quality control checks

- Method development and validation

- Raw material analysis

- Refined product development methods

Contaminant detection and analysis methodology and instrumentation:

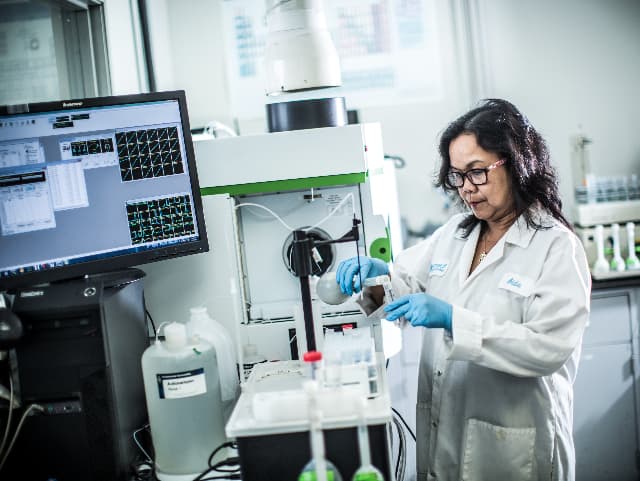

Our contamination services are customized to meet your specific needs, utilizing a wide range of instrumentation and methodologies. We can detect volatile and semi-volatile compounds, as well as perform various non-volatile analyses across a broad spectrum of molecular weights. Our analytical scientists are skilled in developing methods to detect trace organic contaminants in different sample matrices, as well as assessing the potency and purity of active ingredients and excipients.

We can apply internationally recognized standardized methods, transfer analytical methods, or use existing ones. Additionally, we can develop new analytical methods (qualitative and/or quantitative) and, if necessary, validate them to meet regulatory guidelines or other relevant standards. Our advanced instrumentation and techniques include:

- Light Microscopy

- Micro-Fourier Transform Infrared (Micro-FTIR) spectroscopy and Raman spectroscopy, with a large FTIR spectral database

- Scanning Electron Microscopy (SEM) coupled with Energy Dispersive X-Ray Spectroscopy (EDS), 3D imaging available

- Liquid Chromatography (LC), with diode-array detectors

- Gas Chromatography (GC), with liquid and headspace sampling, as well as flame ionization detection (FID)

- Quadrupole/Time of Flight Tandem Mass Spectroscopy (Q-TOF)

Industry-Specific Solutions

We understand the unique challenges across pharmaceuticals, biologics, specialty chemicals, and consumer products. Our testing solutions ensure consistency, safety, and efficacy while meeting industry-specific requirements. For consumer products, we focus on substances of concern, while our pharmaceutical testing aligns with FDA mandates and regulatory guidelines.

Collaborative Expertise

Partner with our seasoned experts who work alongside your team throughout the investigation process. Get remote SEM sessions for real-time collaborative problem-solving, accessing our deep materials science expertise and extensive FTIR spectral database for comprehensive contamination resolution.

Cutting-Edge Equipment We Use

Cutting-Edge Equipment We Use

Our advanced analytical instrumentation includes:

- Micro-FTIR and Raman spectroscopy

- Scanning Electron Microscopy (SEM) with EDS and 3D imaging

- Liquid and Gas Chromatography

- Q-TOF Mass Spectroscopy

- Nuclear Magnetic Resonance (NMR)

- X-Ray Diffraction (XRD)

Which Labs Offer This Service

Which Labs Offer This Service

Our team operates from Life Sciences hubs across the world, providing global access to our expert capabilities. Find your nearest Life Sciences hub on our Locations Page.

Standards we test to and products we test

Pharmaceutical Products:

- Drug products and biologics

- Injectable medications

- Parenteral drug products

- Active ingredients and excipients

Manufacturing Components:

- Raw materials

- Processing aids

- Mixing equipment

- Rubber gaskets

- O-rings

- Lubricants

Packaging Materials:

- Glass containers

- Rubber components

- Aluminum packaging

- Plastic materials

- Paper products

Your Challenges, Our Solutions

Urgent Regulatory Compliance

Manufacturing Quality Concerns

Product Safety Risk Management

Production Process Vulnerabilities

Why Choose Element

Global Leader in Analysis

Advanced Technical Capabilities

Comprehensive Support Approach

Partner in Quality Assurance

Frequently asked questions

How do you help prevent future contamination?

We provide wraparound services including batch-to-batch testing, refined product development methods, quality control checks, and process improvement recommendations.

What's included in your particle analysis capabilities?

We provide comprehensive particle analysis including measurement of particle counts, size, and size distribution. This is particularly valuable when multiple particle types are present in a pharmaceutical product.

Can you analyze residue and discoloration issues?

Yes, we specialize in isolating and identifying stains, discoloration, and residue, even with minimal sample availability.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Trace Metal Testing and Analysis Services

Element offers trace metal testing and impurity analysis services, addressing safety, compliance, and contamination challenges for pharmaceutical products with advanced techniques and global expertise.

Raw Materials and Excipients Testing Services

Element offers expert raw material and excipient testing services, addressing pharma industry challenges with advanced techniques to support quality, safety, and regulatory compliance throughout drug development and manufacturing.

Material Sciences Testing

Our material testing laboratories provide a complete suite of material testing services for pharmaceutical companies.

Elemental Impurities Testing and Analysis

Industry-leading elemental impurities testing for pharmaceuticals. Offering advanced methods, accurate trace detection, and regulatory expertise to support safe and compliant drug development processes.