Physical Characterization of Pharmaceutical Products services

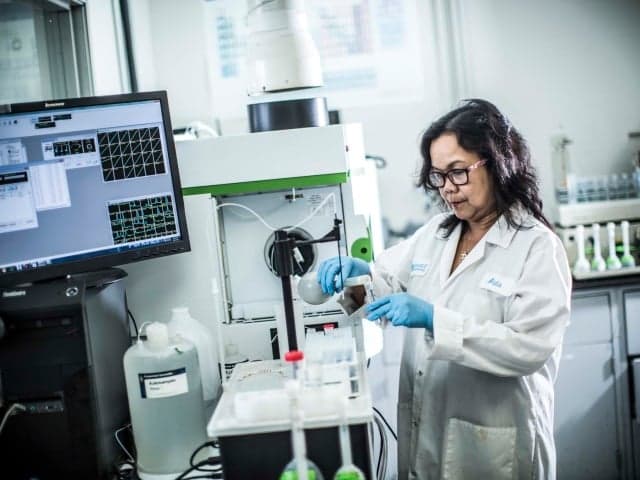

Minimize costly development failures and ensure product stability with our comprehensive physical characterization pharmaceutical testing. From early-stage development through quality control, our experienced scientists help you understand the critical physical properties that impact your product's performance, processability, and market success.

What is physical characterization testing at Element?

Physical characterization testing analyzes the key properties of pharmaceutical materials that affect product performance, stability, appearance, and processability. At Element, we provide comprehensive physical properties testing for pharmaceutical development, from raw materials through to Active Pharmaceutical Ingredients (API), helping you make informed decisions throughout your product lifecycle and solving failure-related problems.

What can Element offer you for physical characterization testing?

Components and materials we test

Components and materials we test

We’re a leading provider of characterization testing for pharmaceutical products. Our scientists have extensive experience with an array of product types, from raw materials to Active Pharmaceutical Ingredients, and our comprehensive testing program helps you understand the physical properties critical to product success and provides you with a valuable competitive advantage in the marketplace.

Key tests offered

Key tests offered

- X-Ray Diffraction (XRD)

- Light Microscopy (LM) and Scanning Electron Microscopy (SEM)

- Differential Scanning Calorimetry (DSC)

- Thermogravimetric Analysis (TGA)

- Particles Size Distribution (PSD)

- Surface area analysis

- Loss On Drying (LOD)

- Physical property measurements (viscosity, refractive index, surface tension, density)

Methods and solutions offered

Methods and solutions offered

Our scientists work closely with you throughout testing, offering flexible solutions tailored to your specific requirements. We provide critical characterization for new product development, specification verification and establishment, formulation and deformulation of products, quality control verification, and problem-solving support for failure-related issues.

Our scientists can apply a variety of physical characterization techniques, including:

- Light Microscopy (LM)

- Microscopic image analysis

- Particles Size Distribution (PSD) by light scattering

- Particle counting

- Surface area by nitrogen gas absorption

- Loss On Drying (LOD)

- Viscosity

- Refractive index

- Surface tension

- Density

Cutting-edge equipment we use

Cutting-edge equipment we use

- X-Ray Diffraction equipment

- Advanced microscopy systems

- Thermal analysis instruments

- Particle analysis technology

- Physical property measurement systems

Which labs offer this service

Which labs offer this service

Our team operates from Life Sciences hubs across the world, providing global access to our expert capabilities. Find your nearest Life Sciences hub on our Locations Page.

Materials we test

Raw Materials:

- Raw pharmaceutical ingredients

- Base materials for formulation

Active Pharmaceutical Ingredients (API):

- New APIs under development

- Existing APIs requiring verification

Finished Products:

- New pharmaceutical products

- Existing pharmaceutical formulations

- Quality control samples

Your Challenges, Our Solutions

Preventing Costly Development Failures

Product Performance Uncertainty

Manufacturing Process Challenges

Quality Control Verification

Why Choose Element

Comprehensive Testing Capabilities

Established Experts

Flexible Custom Solutions

Protected Innovation Journey

Frequently asked questions

What physical properties can impact my pharmaceutical product?

Physical properties affect product performance, stability, appearance, and processability. Understanding these characteristics early in development is crucial for success.

When in the development process should I start physical characterization testing?

The earlier you start the better. Testing from the earliest stage of pharmaceutical development is optimal, giving you a competitive advantage by minimizing potential costly product failures later in the development phase.

What microscopic analysis capabilities do you offer?

We provide both Light Microscopy (LM), Scanning Electron Microscopy (SEM), and microscopic image analysis for detailed characterization of pharmaceutical materials.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Medical Device Testing Services

With Element as your medical device testing partner, you’ll enjoy the benefit of a single comprehensive supplier across feasibility, R&D and prototype trials, through product development, regulatory validation and production quality control.

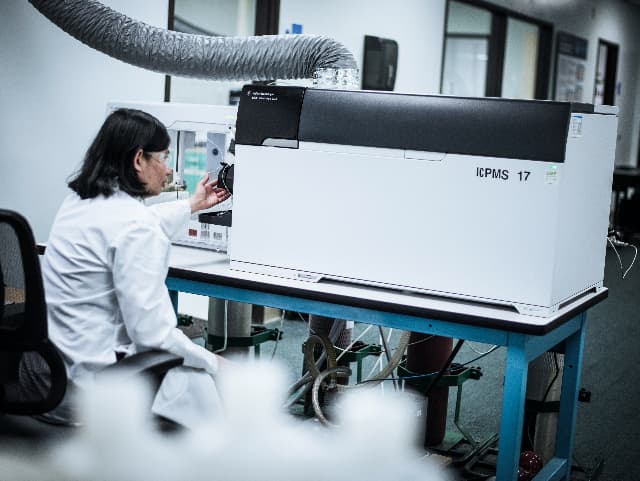

Trace Metal Testing and Analysis Services

Element offers trace metal testing and impurity analysis services, addressing safety, compliance, and contamination challenges for pharmaceutical products with advanced techniques and global expertise.

Raw Materials and Excipients Testing Services

Element offers expert raw material and excipient testing services, addressing pharma industry challenges with advanced techniques to support quality, safety, and regulatory compliance throughout drug development and manufacturing.

Pharmaceutical Medical Device and Product Testing

With Element as your medical device testing partner, you’ll enjoy the benefit of a single comprehensive supplier across feasibility, R&D and prototype trials, through product development, regulatory validation and production quality control.

Material Sciences Testing

Our material testing laboratories provide a complete suite of material testing services for pharmaceutical companies.

Chemical Analysis Services

Element’s chemical analysis services provide accurate material verification, compliance testing, and contamination detection. Our advanced methods deliver reliable insights for product development, quality control, and regulatory standards.