About Element Rolls-Royce, Dahlewitz Materials Testing Laboratory

In collaboration with Element, the Rolls-Royce center of excellence, located in Dahlewitz, Germany, is a leading supplier of materials testing, including multiaxial fatigue capabilities, component vibration, composite blades, and large-scale spin testing that can be used for a wide variety of industry sectors including the Aerospace, Energy, and Automotive markets.

The world-class facility combines leading expertise and technology to solve highly complex problems for customers. The laboratory has an internal workshop and design team that enables quick turn-around times, saving on costly downtime for customer projects.

Services include:

-

Materials testing – complex materials testing projects including high-temperature low/high cycle fatigue, thermo-mechanical fatigue, biaxial fatigue, crack propagation, and multi-axial fatigue are performed. Capabilities include single or multi-axial testing machines.

-

Vibration testing – multiple facilities to conduct vibration tests such as natural frequency, mode shape, damping, and fatigue life.

-

General spinning facility – capabilities include low cycle fatigue (LCF) and over-speed testing.

-

Specialist spinning facility - capabilities include general spinning for low cycle fatigue (LCF) and over-speed testing as well as specialist spinning for multi-functional test rigs and engine development.

The facility has UKAS accreditation to International Standard ISO/IEC 17025:2017, and now has the capacity to offer its innovative services to a broad customer base. For more information, or to speak with our experts directly, please submit your details using the form below.

Compliance and capabilities at Rolls-Royce Dahlewitz

- Materials (for complex materials testing)

- Composite blades

- Components (for vibration and spinning tests)

- ISO/IEC 17025:2017

Global expertise

Working with Element, you have access to our global network of materials testing and product qualification test experts. Meet our Engaged Experts.

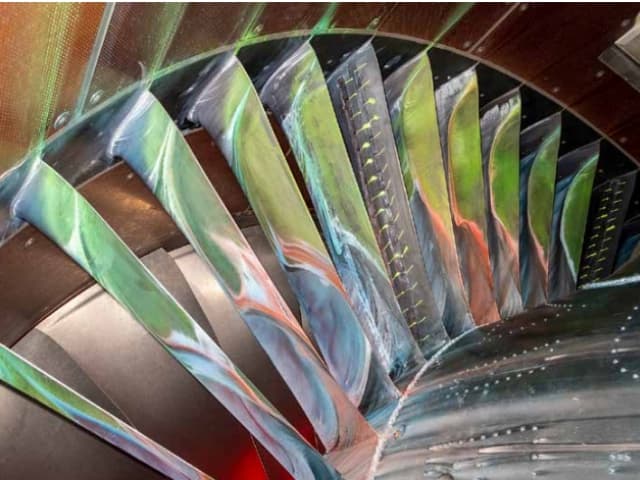

Thermal Paint Temperature Measurement

Thermal Paints are used to provide full surface temperature measurement within concealed areas. They present visual evidence of peak temperatures and isothermal distributions, with temperatures indicated by colour changes or surface texture, that occur at one or more distinct temperatures.

The paints provide temperature distributions for component surfaces that are difficult to obtain such as aero engine turbine blades, vanes, segments, combustors, or rotating components within harsh environments.

Rolls-Royce have been using thermal paints for over 80 years There are a range of paints and services available that include:

- Guidance and recommendation on test planning

- Paint application

- Test design and support

- Post-test analysis

- Results can be displayed through high resolution photos, 3D models, or 3D and 2D temperature embedded images

- Technical report detailing test specification, results and conclusions