Foam Testing Services

Foam testing services are essential for manufacturers facing strict compliance demands, uncertain product durability, and evolving quality standards. At Element, we help you overcome these challenges with independent, expert testing of foam materials and components. From ASTM D3574 compliance to long-term performance validation, we deliver reliable data that supports confident decision-making and ensures your products meet regulatory and customer expectations.

What is foam testing at element?

Foam testing is the scientific evaluation of the mechanical, physical, and chemical properties of foam materials to determine their performance, durability, and regulatory compliance. At Element, we test flexible polyurethane foams and other cellular materials to ASTM D3574 and related standards. We provide precise, repeatable data for both standalone foam materials and complete products, supporting your R&D, quality control, compliance, and product optimization.

What can Element offer you for foam testing?

Key Tests Offered

Key Tests Offered

We can evaluate foam by itself, or as part of a complete product evaluation or in association with product flammability testing or product durability testing. Tests we offer include:

Density - Determines the weight (mass) of a specific volume of foam. Commonly reported at lbs/ft3.

Indentation Force Deflection - Evaluation of the firmness of the foam, and the support provided, at 25% compression, 65% compression, or others.

Compression Set - Evaluation of the thickness recovery of foam after exposure to time and temperature in a compressed state.

Tensile Strength - Measures the tensile breaking strength and elongation of foam specimens.

Tear Resistance - Determines propensity to continue a tear.

Resilience (Ball Rebound) Test - Measures the rebound height of a steel ball dropped onto the surface.

Durability and Fatigue Testing - Various fatigue tests are used to evaluate the thickness change.

Accelerated Aging - Various accelerated aging exposures are used to determine the change in material properties

Components And Products We Test

Components And Products We Test

We test all types of flexible cellular materials, with particular expertise in urethane foams used in mattress and furniture applications. Our testing capabilities cover slab, bonded, and molded urethane foams, both as standalone materials and as part of complete products.

Methods And Solutions Offered

Methods And Solutions Offered

We provide comprehensive testing solutions aligned with ASTM D3574 and other industry standards. Our services include both individual property testing and complete product evaluations, with specialized expertise in mattress and furniture industry requirements.

Standards we test to and materials we test

- Flexible Cellular Materials

- Slab Urethane Foams

- Bonded Urethane Foams

- Molded Urethane Foams

- Foam Mattress Components

- Foam Furniture Components

Your Challenges, Our Solutions

Regulatory Compliance Complexity

Performance Validation Uncertainty

Quality Control Assurance

Product Durability Concerns

Why Choose Element

Global Expert Network

Independent Testing Authority

Complete Product Evaluation

Comprehensive Testing Solutions

Related services

Fire and Flammability Testing Services

Explore the range of fire & flammability testing services from Element. Ensure compliance with global labs, expert guidance & fast results.

Materials Testing Services

View our comprehensive materials testing service range, combining destructive and non-destructive testing for a wide range of materials and industries.

Medical Mattress Testing

Element provides best-in-class hospital medical mattress testing to ANSI/RESNA SS-1, with a team of experts on hand to guide you through the whole testing process.

Polymer Testing & Characterization Services

Maximize your polymer material performance with Element's comprehensive testing services. Our expert analysis translates complex data into actionable insights across your entire product lifecycle.

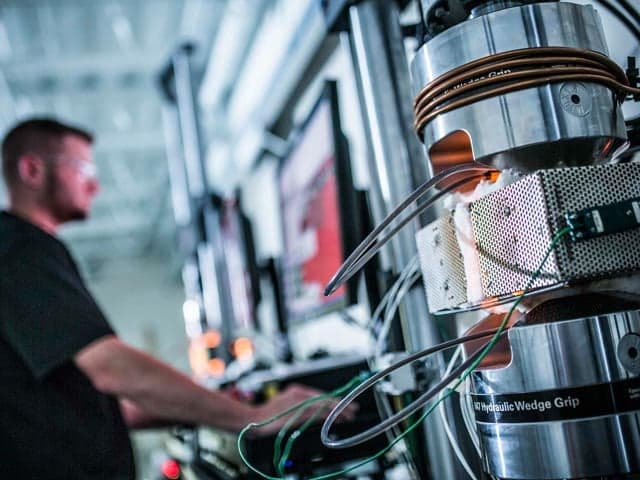

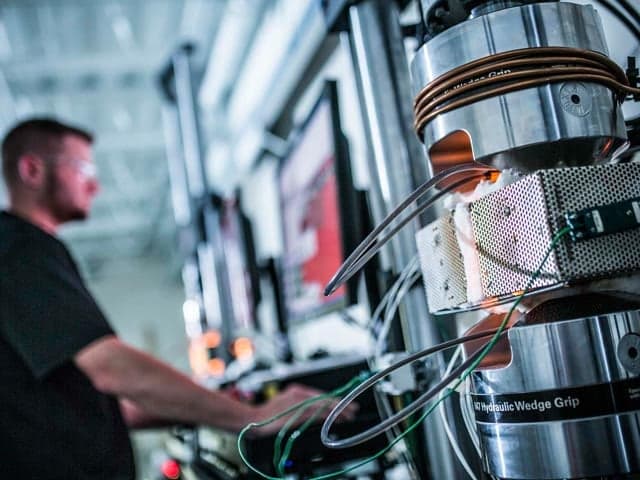

Mechanical Testing Services

Element provides fast, precise mechanical testing services for metals, polymers, and composites, helping industries meet compliance standards and optimize material performance with expert-driven assessments.

Fatigue Testing Services

Element's fatigue testing services analyze material durability under cyclic loads, providing insights into fatigue failure, fatigue life, and performance under real-world conditions.

Bedding & Mattress Testing Services

Element provides expert mattress testing services to manufacturers in the consumer, medical, and institutional industries to evaluate the flammability, durability, and performance of their product, and help them to bring safer and quality products to the market.

Frequently asked questions

What is the most common test standard for urethane foam?

ASTM D3574 is the most commonly referenced test method for urethane foam, containing several individual test methods for determining various properties of flexible cellular materials.