Impact Testing of Polymers and Composites

Ensure your products meet rigorous safety and performance standards with comprehensive polymer and composite impact testing. From Charpy and Izod testing to multiaxial impact analysis, we help aerospace, pharmaceutical, and automotive manufacturers validate product durability, ensure regulatory compliance, and optimize material selection – all while minimizing risk and maximizing product longevity.

What is Impact testing of Polymers and composites at Element?

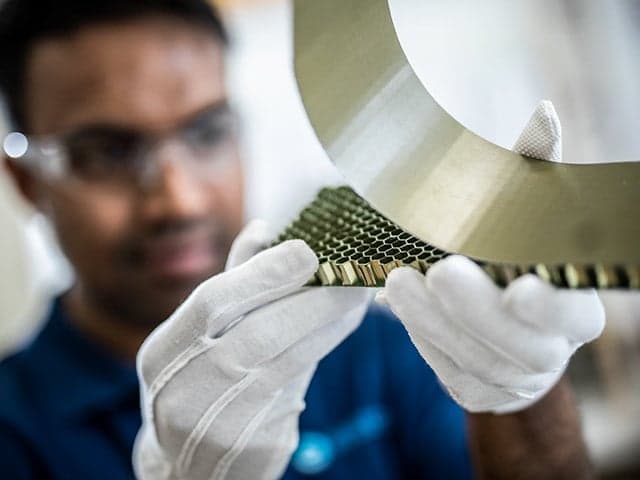

Impact testing evaluates how materials respond to sudden force application, measuring deformation, fracture patterns, and energy absorption. At Element, we replicate real-world conditions to assess your polymers and composites' resilience, providing crucial insights for material selection and design optimization across aerospace, pharmaceutical, and automotive applications.

What can Element offer you for impact testing of polymers and composites?

Key tests offered

Key tests offered

Element provides a variety of impact strength testing methods tailored to your project needs. Our experts collaborate with you to determine the most suitable method for your material or product. Specializing in testing plastics, elastomers, and composites, we ensure comprehensive evaluation across various materials. Additionally, we offer testing solutions for packaging, containers, telecommunications wire, cables, and connectors customized to your specific requirements.

Our testing procedures include:

- Charpy and Izod Testing

- Gardner Impact Testing (also known as Falling Dart Impact)

- Multiaxial Impact (Instrumented Impact) Testing

- DuPont Impact Testing

- Tensile Impact Testing

Components and materials we test

Components and materials we test

We test a comprehensive range of polymers, elastomers, and composites. Our specialized testing capabilities extend to packaging, containers, telecommunications wire, cables, and connectors. Each material undergoes rigorous evaluation tailored to your specific industry requirements and performance needs.

Methods and solutions offered

Methods and solutions offered

Our testing methods align with ASTM and ISO standards while accommodating custom requirements. We employ advanced procedures to evaluate impact resistance at various production stages, ensuring consistent quality throughout your manufacturing process. Our approach combines standardized testing with tailored solutions for your specific application needs.

Future-proof support

Future-proof support

We help you optimize product lifecycle management through comprehensive testing and analysis. Our experts work with you to develop strategic maintenance plans, identify optimal part replacement schedules, and enhance long-term product performance. This proactive approach helps you stay ahead of maintenance challenges and maximize product longevity.

Standards we test to and components we test

American Society for Testing and Materials:

- ASTM D256

- ASTM D746

- ASTM D1822

- ASTM D2794

- ASTM D3763

- ASTM D4226

- ASTM D4495

- ASTM D4812

- ASTM D5420

- ASTM D6110

- ASTM D7136

- ASTM E23

British Standards:

- BS 131

International Standards Organization:

- ISO 179

- ISO 180

- ISO 6603-2

- ISO 7765-1

Japanese Industrial Standards:

- JIS K 5600-5-3

Industrial Materials:

- Plastics

- Elastomers

- Composites

- Structural adhesives

- Coatings

Commercial Products:

- Packaging

- Containers

- Telecommunications wire

- Cables

- Connectors

Your Challenges, Our Solutions

Product Failure Risk

Regulatory Compliance Hurdles

Material Selection Uncertainty

Manufacturing Process Validation

Element Experts at your service

Why Choose Element

Mitigate Risk

Meet Industry Compliance

Make Informed Material Selections

Validate Your Manufacturing Process

Frequently asked questions

Why is impact testing important for my products?

Impact testing provides crucial insights into your materials' performance under stress, helping prevent failures, ensure compliance, and optimize product design. It's essential for validating durability and safety across aerospace, pharmaceutical, and automotive applications.

How does impact testing help with long-term maintenance planning?

Our testing identifies material limits and performance thresholds, enabling you to develop strategic maintenance schedules and plan proactive part replacements. This data-driven approach optimizes your product lifecycle management and helps prevent unexpected failures.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Non-Metallic Materials Testing

Element evaluates your non-metallic materials for strength, flexibility, fatigue, and various other physical properties that metals are tested for. Learn more.

Polymer Testing & Characterization Services

Maximize your polymer material performance with Element's comprehensive testing services. Our expert analysis translates complex data into actionable insights across your entire product lifecycle.

Composites Testing

Expert composite material testing with ISO 17025 accredited services. From raw materials to fatigue performance, get accurate results that enhance reliability and meet standards.

Polymer Failure Analysis Services

Element's expert polymer failure analysis services investigate the cause of failure so you can take corrective action, limit damage, and prevent similar product failures in future.

Charpy Impact Testing Services

Charpy impact testing provides a wealth of material data with a single impact strength test, ensuring safety and integrity of components and products. Learn More about our ISO 17025 accredited services.

Tensile Testing

Element's tensile testing provides accurate data on material strength, stiffness, and durability. Browse our range of tensile testing services including Open Hole tensile testing.

Mechanical Testing of Composites

Element provides expert mechanical testing for composite materials, ensuring strength, durability, and compliance with industry standards. Services include tensile, shear, compression, and fatigue testing.