Strain Analysis Services

Unlock the hidden performance potential of your critical components with Element's precision Strain Analysis Services. We transform your complex material stress challenges into actionable insights, helping you validate design, predict durability, and ensure peak performance across aerospace, defense, and industrial sectors.

What is Strain Analysis Testing at Element?

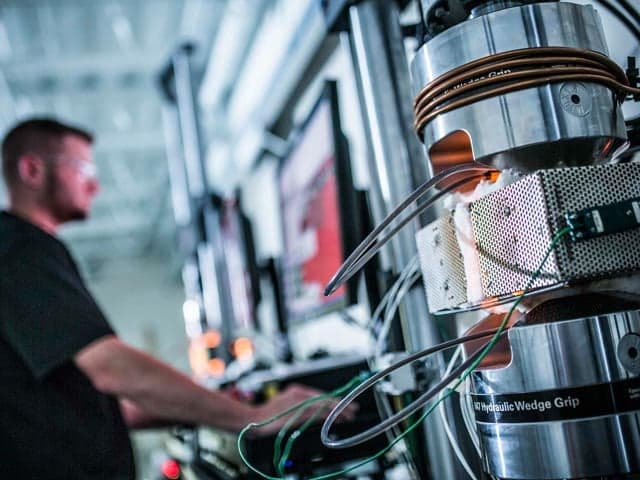

Strain analysis is a sophisticated testing technique that measures material deformation under various loading conditions. At Element, we provide comprehensive strain analysis services that quantify how materials respond to stress, using advanced strain gaging techniques to deliver critical performance insights across multiple industries. We offer both physical and optical testing methodologies, ensuring flexibility in testing environments.

What Can Element Offer You For Strain Analysis?

Key tests offered

Key tests offered

In a stress-strain analysis, we apply strain gages to your product to determine the stresses acting on the part. That allows us to carry out the following kinds of analysis:

- Static and dynamic loading analysis

- Torque strain measurements

- Temperature stress testing (-250°C to +1000°C)

- Fatigue life estimations

- Performance parameter validation

Methods and solutions offered

Methods and solutions offered

Element can install and measure strain gages in virtually any condition, including extreme environments such as high temperatures, cryogenic conditions, and liquid immersion. Our cutting-edge data acquisition systems provide:

- Six fully integrated data acquisition systems, each capable of 300+ channels (clarifying system capabilities)

- Real-time data collection supplemented with digital video, CAN & LIN bus protocols

- On-site instrumentation services for international and domestic projects

- Correlation and validation of computer models, including FEA and dynamic modeling

Pioneering Research Advantage

We boast the first industry database for strain-life fatigue in cast iron, demonstrating our commitment to technological innovation and advanced materials research

We provide stress-strain analysis and strain gaging services for products and materials in Transportation, Defense, Aerospace and industrials. From individual components and subsystems to full-size products, we support engineering designs, product validation, strain life predictions and validation of analytical models such as FEA and dynamic modeling.

Our data acquisition and engineering support specialists work with you to create the optimal test procedure, developing plans for evaluating your materials and products that meet the engineering design criteria.

Components and materials we test

Components and materials we test

Element offers strain analysis across a diverse range of materials including composites, glass, ceramics, steels, and alloys. Our expertise spans transportation, defense, aerospace, and industrial sectors, testing everything from individual components to full-size products.

Cutting-edge equipment we use

Cutting-edge equipment we use

We can install and measure strain gages in virtually any condition, including low and high-temperature environments and immersion in liquids. Our state-of-the-art facilities incorporate:

- Six data acquisition systems with 300+ measurement channels

- Telemetry systems for rotating machinery

- Digital video and communication protocol data recording

- Advanced strain gage installation capabilities

- Computer Model Correlation & Validation

- On-Site/In-Field instrumentation and data acquisition services

- Acquisition systems capability of recording real time data to supplement strain measurements including digital video, CAN & LIN bus protocols

- Strain gage temperature ranges from -250°C to +1000°C

- Application of any strain gage virtually any substrate including composites, glass, ceramics, steels & alloys

- Torque strain gage applications both external and internal shaft installation with telemetry systems for rotating machinery

Materials we test

- Composites

- Glass

- Ceramics

- Steels

- Alloys

- Rotating machinery components

- Structural materials

Your Challenges, Our Solutions

Performance Uncertainty

Material Durability Concerns

Complex Testing Made Simple

Technological Validation

Element Experts at your service

Why Choose Element

Extreme Testing Versatility

Cutting-Edge Innovation

Comprehensive Solution Provider

Comprehensive Industry Support

200+Years

6Data Acquisition

300+Simultaneous

-250°C to +1000°CStrain gage

Frequently asked questions

What environmental conditions can you test in?

We can install and measure strain gages from -250°C to +1000°C, including immersion in liquids and various challenging environments.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Materials Testing Services

View our comprehensive materials testing service range, combining destructive and non-destructive testing for a wide range of materials and industries.

Non-Destructive Testing (NDT) and Inspection Services

Get precise, reliable non-destructive testing (NDT) to detect flaws, verify material integrity, and meet industry standards, saving time and reducing risk. View services.

Fatigue Testing Services

Element's fatigue testing services analyze material durability under cyclic loads, providing insights into fatigue failure, fatigue life, and performance under real-world conditions.

Climatic & Environmental Chamber Testing Services

Test your products' durability with environmental chambers at Element. Accurately simulate real-world conditions to meet industry standards and ensure performance.