Using Finite Element Analysis (FEA) to Identify Delamination of Composites Materials

In this article, Element expert Adam Thompson, Lead Consultant with over a decade in structural analysis, demonstrates how FEA predicts catastrophic delamination in aerospace composites before failure occurs. This guide shows real-world analysis of AS4-PEEK flanges under dynamic loading, revealing how simulation identifies critical failure points and optimizes designs to prevent costly disasters.

Delamination is an important factor to consider when testing composites, particularly when comparing this to metallic materials.

The delamination of composite materials can be caused by high interlaminar stresses in conjunction with low through-thickness strength which puts composite materials at greater risk of failure.

Types of delamination

Delamination is a common failure that leads to the separation of the layers or the reinforcement within the composite material. Delamination failure can be caused by a fracture in the adhesive, resin, or within the reinforcement, or it can be caused by debonding of the resin from the reinforcement.

The example below uses advanced Finite Element Analysis (FEA) to look at delamination of a bolted joint due to an overload during operation.

How to prevent delamination in composite materials

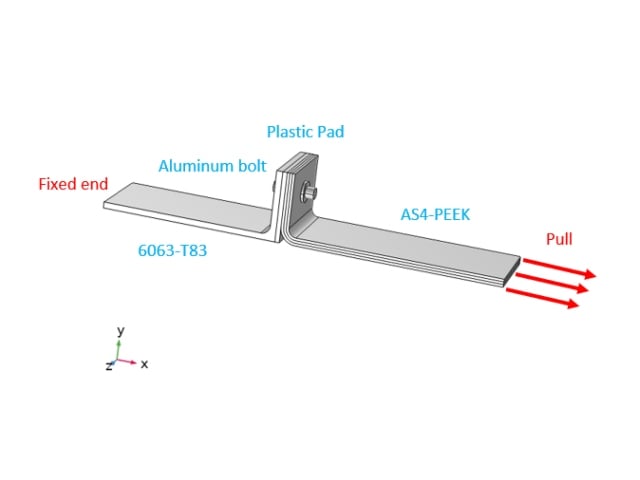

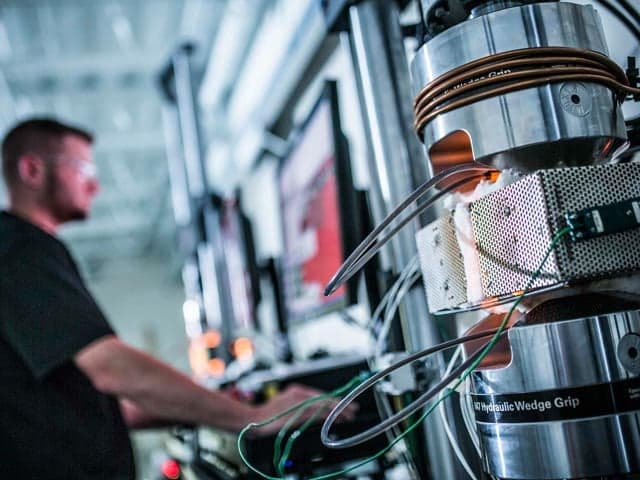

Using the FEA method, we can simulate the delamination of the structural component. In the example below we look at the structural evaluation of a multi-layered composite flange (AS4-PEEK) under dynamic loading.

The diagram illustrates the dynamic assessment of a composite flange connected to an aluminum grade, heat-treated part (Al063-T83), which is separated by a plastic spacer and kept in place using aluminum bolts.

Figure 1: Flange assembly and boundary conditions.

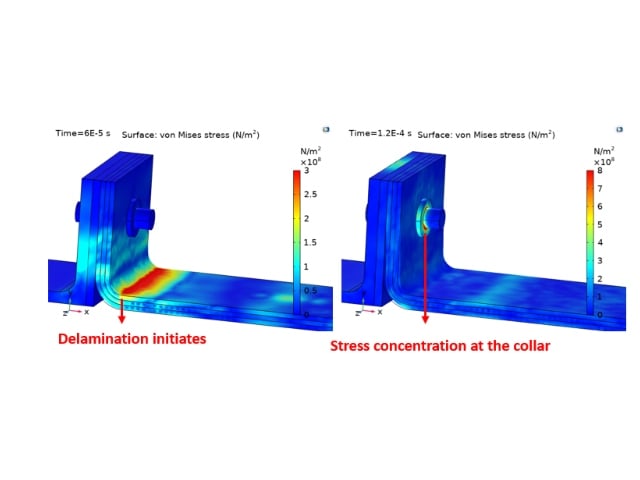

The composite flange has a steep radius which is a critical location for delamination initiation as the laminate has reduced capacity for out-of-plane loading.

Using FEA analysis, we can simulate, and confirm the concern over the delamination initiation in the loading phase at a small flange opening angle, as well as stress concentration in the collar.

Figure 2: Using FEA to show delamination initiation and stress concentration.

We can use this to study and simulate, design improvements such as increasing the composite thickness, using a crushable bolt collar that absorbs energy through its deformation, or testing a different flange architecture. Using traditional FEA of composite materials and parts, it enables us to:

- Predict critical failure events such as delamination and debonding at the locations of interest.

- Size the flange parts to optimize the design by increasing loading capacity, reducing weight, and therefore cost.

- Create a digital replica, or digital twin of the dynamic test and use that to reduce qualification costs.

The Element advantage

At Element, our digital engineering and composites testing experts work in partnership and assist clients from verification to validation, throughout the entire product life-cycle, to ensure materials, products and components are at the forefront of innovation, and perform as expected.

Related Services

Polymer Testing & Characterization Services

Maximize your polymer material performance with Element's comprehensive testing services. Our expert analysis translates complex data into actionable insights across your entire product lifecycle.

Finite Element Analysis (FEA) Services

Advanced Finite Element Analysis (FEA) services simulate product performance, optimize designs, and predict failures, addressing structural, thermal, and dynamic challenges across industries with expert solutions.

Materials Testing Services

View our comprehensive materials testing service range, combining destructive and non-destructive testing for a wide range of materials and industries.

Advanced Modeling and Simulation Services

Elevate your project with Element's modelling and simulation services, including fluid simulation, CFD, FEA, DEM, and electromagnetics. Our industry-leading expertise ensures precision, cost savings and regulatory compliance at every step.

Digital Twin Solutions and Services

Enhance efficiency with our Digital Twin Solutions. Predict performance, reduce costs, and optimize operations with real-time virtual replicas of your assets.