Chemical exposure testing applications

In this article, Element expert Dan Olson reveals how chemical exposure testing evaluates product durability against harsh acids, bases, and solvents to predict real-world performance. This guide demonstrates systematic testing - tracking appearance changes, weight variations, and tensile strength degradation - helping manufacturers ensure their polymers, components, and assemblies withstand challenging chemical environments in industrial applications.

It is vital that your products are able to withstand harsh conditions involved in your components’ end-use. Chemical exposure testing can determine your product’s stability when exposed to a chemical or substance, and can help you identify and resolve concerns relating to your product’s durability and lifetime.

Compatibility studies can be performed to ASTM methods, your specifications, or a proprietary method. In addition, the testing can also be based on competitor claims or to duplicate a previous study. Read on for examples of applications of chemical exposure testing.

Evaluating a product for changes in appearance

In a recent chemical exposure study, a product was exposed to three different liquid environments over a seven day period. In this case, the entire product was sprayed with an acid, a base, or an organic solvent once per day. The client asked that the entire product be evaluated for change in appearance of any part of the product including the label, screws, mating areas of connected components parts and each component part itself. We provided the images below to our customer showing the acidic, alkaline and organic solvent effects on the products following the chemical exposure. This allowed our client to determine if the products would satisfactorily withstand the harsh conditions they could be exposed to.

Figure 1: A metallic surface compromised by acid

Figure 2: Pitting effects of alkali exposure.

Figure 3: The window of the “open” indicator was affected by the organic solvent

Evaluating polymers for changes in weight, appearance and tensile strength

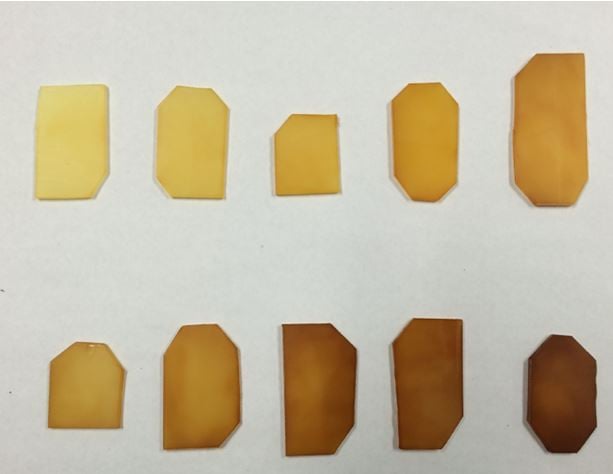

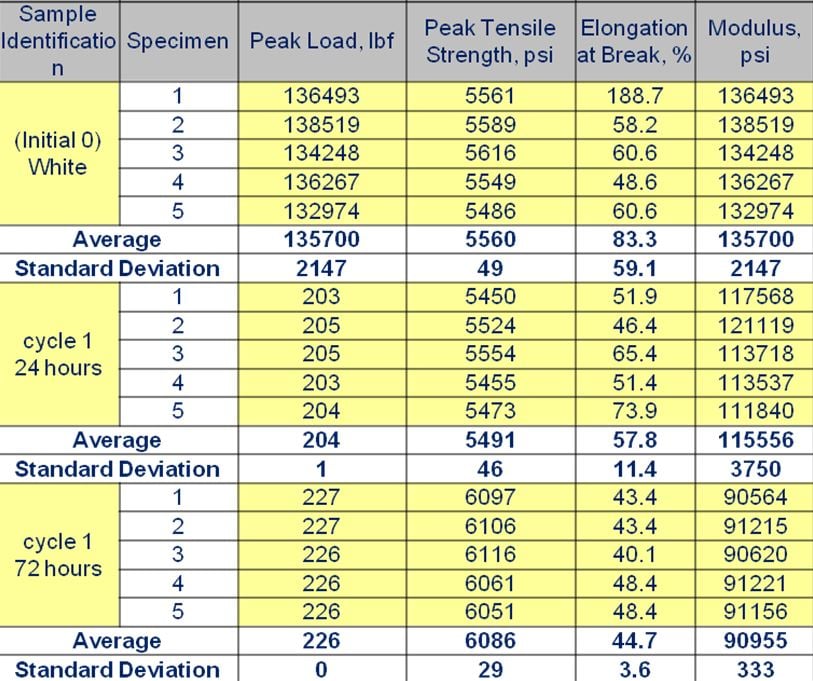

Our next study involved the exposure of three different polymers to two different solutions used in the oil industry. The study involved evaluating the sample at designated time intervals over varying temperature and solution conditions. At each stage of the chemical exposure experiment, our client asked for data (see table 1) relating to weight and appearance changes as well as tensile strength. The data was then provided to our customer enabling them to determine if their product would be fit for purpose.

Figure 1: Change in appearance of the samples over the course of the study

Table 1: Tensile data for the same polymer after one cycle of exposure.

What do you need for a chemical exposure evaluation?

Before a chemical exposure test can be performed, the parameters of the study must be defined.

Examples of these parameters include:

- a portion of the sample to be exposed

- number of specimens exposed to each environment

- type of chemical environment

- length of exposure time

- criteria for evaluation

Evaluation criteria may include:

- visual evaluation

- change in mass

- change in volume

- dimensional changes such as length, thickness, diameter, hardness evaluation, and other physical dimensions

Our Engaged Experts will help guide your chemical exposure evaluation criteria to ensure the project scope meets your needs.

For more information about our chemical exposure testing or other services offered, contact us today.

Related Services

Chemical Analysis Services

Element’s chemical analysis services provide accurate material verification, compliance testing, and contamination detection. Our advanced methods deliver reliable insights for product development, quality control, and regulatory standards.

Failure Analysis Services

Need expert Failure Analysis Services? Identify root causes fast with Element's advanced testing, global reach, and rapid turnaround. Get expert insights today.

Energy Coatings Testing Services

Protect your critical energy assets with Element's specialized coatings testing. We simulate extreme offshore and pipeline conditions to validate performance, prevent costly failures, and ensure compliance. Learn More.

Corrosion Testing Services

Learn about our range of ISO/IEC 17025-accredited corrosion testing services. Safeguard your assets, ensure reliability, qualify welds, assess materials and enhance safety.