High-Fidelity CFD Modeling to Determine Flare Destruction Efficiency for Methane Emissions

This article details how Element's Digital Engineering team, led by Tom Elson, employed high-fidelity Computational Fluid Dynamics (CFD) modeling to assess methane destruction efficiency in oil and gas flares.

Background

Emissions and their impact on the environment are a major focus for companies and operators in the Oil and Gas Industry. Methane emissions from flaring are particularly concerning, as methane is 26 times more potent as a greenhouse gas than carbon dioxide. Previous studies suggested a flare destruction efficiency between 98-99%, but new technologies and methods have brought this into question. Element Digital Engineering developed a methodology using Computational Fluid Dynamics (CFD) to predict the methane destruction efficiency of an operational flare. Our client sought to determine the efficiency of their flare under various conditions to identify opportunities for improvement.

The challenge

Our client needed to understand the operational methane destruction efficiency of their flare under a range of conditions. This required a detailed analysis of how different factors, such as crosswind speeds and the positioning of ignition sources, impact the efficiency. The primary objective was to identify areas for improvement to minimize methane emissions and meet environmental regulations.

The solution

Element Digital Engineering created a comprehensive CFD model of the client's flare system. This model included:

- A 3D representation of the flare geometry, including flare tips, ignition sources, wind fences, and platforms.

- Wind speed calculations at the flare tip using an atmospheric boundary layer profile.

- Transient calculations of species transport with a complex chemistry combustion model to predict flare performance accurately.

- Extensive monitoring of combustion reactants and products to ensure precise and reliable destruction efficiency measurements.

The model evaluated the flare under normal, startup, and extreme operating conditions. Sensitivity studies helped determine the combustion reaction temperatures necessary to ensure accurate destruction efficiency reporting.

The result

The analysis revealed a wide range of destruction efficiencies, from 52% to 95%, depending on the operating conditions. It highlighted the sensitivity of flare efficiency to crosswind conditions and the positioning of ignition sources. For example, at mean operating conditions with a 20th percentile crosswind speed, the methane exit velocity was significantly lower than the crosswind speed, causing considerable methane dispersion and reduced combustion efficiency.

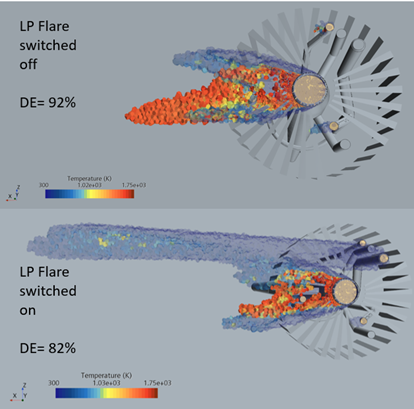

Visualizations of the combustion profile under different crosswind velocities provided insights into the mechanisms impacting destruction efficiency. The study also identified a design improvement opportunity for the flare tip, suggesting adding a dedicated pilot for the low-pressure (LP) flare to enhance overall efficiency.

Visualizations of the combustion profile under different crosswind velocities provided insights into the mechanisms impacting destruction efficiency. The study also identified a design improvement opportunity for the flare tip, suggesting adding a dedicated pilot for the low-pressure (LP) flare to enhance overall efficiency.

The findings enabled our client to develop plans to reduce greenhouse gas emissions and improve flare efficiency. This case study demonstrated that destruction efficiency varies widely across different conditions, often falling below the previously assumed 98-99%.

Why Choose Element

Industry-Leading Digital Engineering Expertise

Proven Emissions Reduction Solutions

Comprehensive Flare System Optimization

Regulatory Compliance Support

Related Services

Computational Fluid Dynamics

We use Computational Fluid Dynamics (CFD) to simulate and analyze complex problems involving fluid-fluid, fluid-solid, and fluid-gas interactions.

Flaring Emissions and Biogas Emissions Monitoring Services

Element's flaring and biogas emissions monitoring ensures regulatory compliance with accurate testing, advanced Phoenix Mast technology, and expert analysis. Our UKAS-accredited services deliver safe, efficient, and cost-effective solutions tailored to landfill, wastewater, and biogas facilities.

Oil and Gas Testing

Element offers a wide range of Oil & Gas testing services, including mechanical and NDT testing, structural and corrosion testing, and failure analysis. Learn more.

Environmental Testing Services

Our experts and network of accredited laboratories offer environmental testing services for water, soil, sediments, waste, air quality, emissions and more. Learn More.

Digital Engineering Services

Element's Digital Engineering Services enhance reliability, reduce costs, and accelerate innovation through advanced simulations and data-driven insights. Our customized solutions streamline project lifecycles, ensuring optimized designs, regulatory compliance, and future-ready technology.