Modeling Hydrogen Dispersion Mitigation in an Enclosed Space

This case study by Tom Elson demonstrates how Element Digital Engineering used Computational Fluid Dynamics simulations to assess hydrogen dispersion and evaluate mitigation strategies in a mobile containerized workshop servicing hydrogen fuel cells.

Background

Hydrogen, a pivotal element in the net-zero energy transition, finds its applications spanning across energy, civil infrastructure, and transportation. Containerized power plants, offering mobile and modular green hydrogen solutions, are increasingly adopted for remote applications. However, the unique properties of hydrogen – such as a wide flammability range, a colorless and odorless flame, and high diffusivity, being lighter than air – elevated the risk of hydrogen dispersion in confined spaces.

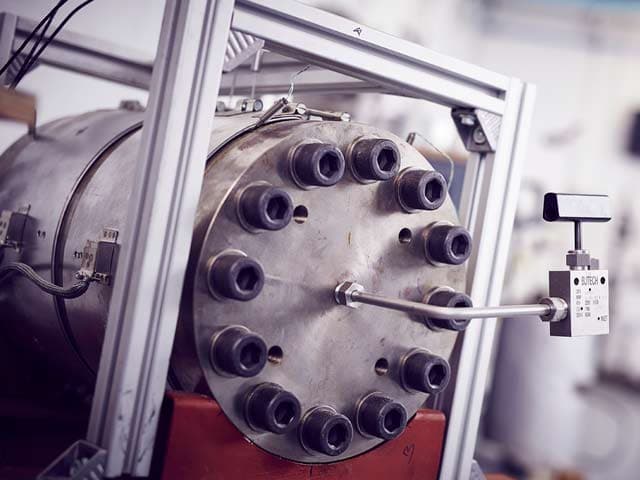

This case study showcases how Element Digital Engineering leverages Computational Fluid Dynamics (CFD) simulation to enhance the safety assessment of mobile containerized workshop units servicing hydrogen fuel cells in remote power applications. The workshop in question features a pressurized 35-bar hydrogen supply pipe, posing a potential risk for hydrogen dispersion due to leakage. An installed leakage mitigation system, equipped with a shutoff valve and an extraction fan driven by gas detection sensors, aims to manage this risk. The failure scenario analyzed involves a full-bore hydrogen feed pipe failure, leading to pressurized hydrogen dispersion into the workshop unit.

A critical aspect under review was the sensor placement’s efficacy in ensuring the leak mitigation system’s performance, crucial for keeping hydrogen concentrations below 25% of the Lower Explosive Limit (LEL) throughout the event, thereby minimizing the risk of hydrogen dispersion.

The challenge

The core challenge addressed in this study was understanding the implications of a pipe failure event on system performance, particularly concerning pressurized H2 gas release into an unventilated, sealed room and its subsequent hydrogen dispersion. Accurately predicting the dynamics of the hydrogen gas jet at the leak source and the gas plume’s behavior, especially near the ceiling, was essential. This required modeling the gas detection process, activation of safety mechanisms, and key outcomes like the residence time and concentration of the hydrogen gas cloud, providing insights into the overall efficacy of the safety system against hydrogen dispersion.

The solution

Element Digital Engineering boasts a wealth of experience in employing Computational Fluid Dynamics (CFD) for assessing the safety and performance of critical engineering systems across sectors. This expertise extends to simulating gas dispersion and gas cloud explosion scenarios, including hydrogen dispersion. Utilizing the commercial CFD code STAR-CCM+ by SIEMENS, the team simulated the leak event as an unsteady, turbulent, and compressible multispecies gas flow, enabling an accurate depiction of hydrogen dispersion within the container environment. Adaptive mesh refinement methods and custom field functions modeled the safety systems’ response to detected hydrogen concentrations, setting the activation threshold at 25% LEL.

The result

The analysis successfully predicted the pipe failure scenario’s consequences, underscoring the hydrogen dispersion risk – a vital input for the system’s overall safety evaluation. The simulation revealed that the failure produced a high-velocity jet, forming a concentrated H2 cloud near the ceiling, with the central sensor’s detection and mitigation system activation occurring within approximately 19 seconds of hydrogen dispersion. This CFD simulation capability facilitated a cost-effective virtual verification of the mitigation system’s effectiveness against hydrogen dispersion, serving as a significant risk management tool. The insights gained also informed the optimization of sensor placement, enhancing system performance and coverage against hydrogen dispersion scenarios.

Influence of forced ventilation on hydrogen concentrations in a closed environment.

Why Choose Element

Proven Hydrogen Safety Expertise

Advanced CFD Risk Modeling

Optimized Sensor Placement

Cost-Effective Virtual Validation

Related Services

Hydrogen Testing

Element performs hydrogen testing, including hydrogen piping system and pipeline testing according to ASME B31.12, the most comprehensive standard currently available for designing steel piping systems that carry gaseous hydrogen.

Energy Testing Services

Element provides expert testing to ensure energy materials are safe, reliable, and compliant, supporting both traditional and renewable energy sectors with comprehensive testing solutions.

Digital Engineering Services

Element's Digital Engineering Services enhance reliability, reduce costs, and accelerate innovation through advanced simulations and data-driven insights. Our customized solutions streamline project lifecycles, ensuring optimized designs, regulatory compliance, and future-ready technology.

Computational Fluid Dynamics

We use Computational Fluid Dynamics (CFD) to simulate and analyze complex problems involving fluid-fluid, fluid-solid, and fluid-gas interactions.

35bar

25%of the Lower Explosive Limit (LEL)

19seconds

100%pipe failure (full-bore)