Predicting Component Life with Erosion Modeling

Background

Oil and gas production systems and chemical process lines are continuously subjected to erosive conditions where fluid-transported particles gradually wear away pipe walls and components. Operators need accurate understanding of when ultimate failure is likely to occur – but, for decades, they have relied on empirical formulas and conservative maintenance schedules to prevent catastrophic failures.

The challenge

Traditional erosion prediction methods utilize empirical formulas that account for pipe material properties and particle characteristics, but fail to capture a critical factor: how the erosion process itself changes the local flow dynamics. As a component begins to erode, the changing geometry creates new flow patterns, altering shear stresses and subsequent erosion rates. These complex interactions meant conventional models were providing overly conservative predictions, leading to premature component replacements. A more accurate modeling approach was needed that could account for these evolving conditions, to optimize maintenance schedules while ensuring operational safety.

The solution

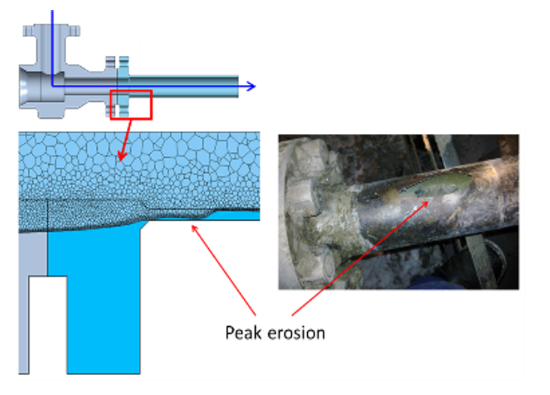

Element collaborated with Siemens Digital Industries Software to develop an innovative solution using morphing-mesh Computational Fluid Dynamic (CFD) methodology. This revolutionary approach allowed the flow domain to change as it was eroded, changing local shear stresses and erosion rates. These models were then validated against experimental work.

The result

The advanced erosion modeling approach delivered exceptional results, accurately predicting both the location of component burn-through and the time to failure. This offered potential in a number of ways:

- Extending component life through more accurate replacement scheduling

- Annual cost savings from reduced component replacements

- Decreased production downtime by improving overall operational efficiency

- Enhanced safety protocols based on more reliable predictive data

- Optimized design modifications for erosion-prone components

These improved simulations can now be used by operators to confidently extend component life while reducing replacement costs and maintaining the highest safety standards.

Why Choose Element

Related Services

Oil and Gas Testing

Element offers a wide range of Oil & Gas testing services, including mechanical and NDT testing, structural and corrosion testing, and failure analysis. Learn more.

Full and Small Scale Pipe Testing

Element provides full-scale pipe testing services to evaluate in-service behavior of your assets and determined potential failure conditions.

Pipeline and Field Joint Coatings

Element provides expert pipeline and field joint coating testing to prevent corrosion, validate performance under extreme conditions, and support compliance with ISO 21809 standards for long-term infrastructure integrity.

Computational Fluid Dynamics

We use Computational Fluid Dynamics (CFD) to simulate and analyze complex problems involving fluid-fluid, fluid-solid, and fluid-gas interactions.