Foot, Ankle, and Shoulder Replacement Implant Testing

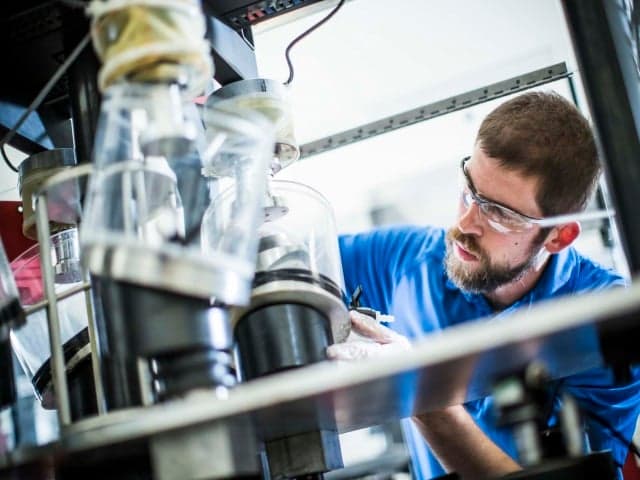

Get comprehensive testing solutions for foot, ankle, and shoulder replacement implants through a single trusted provider. With extensive experience in extremity implant testing, we support both standard and unique device designs with testing that meets ASTM requirements and provide end-to-end guidance from feasibility studies through regulatory submission.

What is Foot, Ankle, and Shoulder Replacement Implant Testing at Element?

Foot, ankle, and shoulder replacement implant testing evaluates devices for safety and performance before market approval. While shoulder replacements are less common than lower extremity replacements, they're vital in eliminating arthritis effects and joint problems. At Element, we provide mechanical testing and metallographic evaluation for all extremity implants.

What Can Element Offer You For Foot, Ankle, and Shoulder Replacement Implant Testing?

Components and products we test

Components and products we test

At Element we test shoulder replacements, total ankle replacements, foot implants, and various small joint orthopedics including wrist and elbow devices. Our capabilities support evaluation of both traditional designs and novel devices with custom protocols, with specialized expertise in glenoid components, shoulder constraints, and total ankle replacement systems as they become increasingly important treatment options.

Key tests offered

Key tests offered

Shoulder Implant Testing

Element provides comprehensive testing for total shoulder replacements, including fatigue testing, glenoid shear, glenoid loosening, and shoulder constraint testing, all performed to ASTM standards or custom protocols. We also conduct shoulder replacement wear testing using unique, proprietary in-house methods.

Foot and Ankle Implant Testing

With the growing popularity of total ankle replacements, Element offers fatigue, constraint, and wear testing for ankle implants, following ASTM F2665 standards, to support the latest advancements in ankle arthritis treatment.

Within these, we provide essential testing capabilities including:

- Flex and Bend Testing

- Shear Testing

- Particulate Analysis

- Range of Motion

- Feasibility Studies

- Glenoid Loosening Testing

- Constraint Testing

- Multi-axis testing

Methods and solutions offered

Methods and solutions offered

We perform testing to recognized ASTM standard methods and develop custom protocols for unique or novel designs. Our team provides comprehensive in-house testing and project management support through every stage - from initial feasibility studies and test design to metallographic evaluation and final regulatory submission. We specialize in both mechanical testing and particulate analysis for complete device assessment.

Which labs offer this service

Which labs offer this service

Our Cincinnati laboratory is Element's global Center of Technical Excellence for medical device testing, supported by our expert team operating from strategically located medical device industry hubs. Find your nearest lab on our Locations Page.

Extremity device expertise

Extremity device expertise

We specialize in testing emerging technologies like total ankle replacements, which the American Academy of Orthopaedic Surgeons notes are becoming the treatment of choice for many patients with ankle arthritis.

Standards we test to and components we test

American Society for Testing and Materials:

- ASTM F1378

- ASTM F1829

- ASTM F2028

- ASTM F2665

- ASTM F1781

- ASTM F1357

- ASTM F2887

Shoulder implants

- Total shoulder replacement devices

- Glenoid components

- Shoulder constraint systems

Ankle and foot implants

- Total ankle replacement (TAR) devices

- Foot implants

- Ankle replacement systems

Small joint orthopedics

- Wrist implants

- Elbow implants

- Other small joint orthopedic devices

Your Challenges, Our Solutions

Growing market demand for extremity implants

Emerging technology validation

Managing multiple testing programs

Understanding regulatory requirements

Element Experts at your service

Why Choose Element

Complete testing ecosystem

Custom protocol development

Regulatory submission support

Technical excellence near you

Related services

Medical Device Testing Services

With Element as your medical device testing partner, you’ll enjoy the benefit of a single comprehensive supplier across feasibility, R&D and prototype trials, through product development, regulatory validation and production quality control.

Wear Testing of Medical Devices

Element can handle every aspect of your medical device wear test program, no matter how long you want the tests to run for or how many repeats you need.

Orthopedic Device Testing Services

Accelerate orthopedic device development with Element's comprehensive testing services. From hip to spinal implants, we ensure regulatory compliance while reducing time-to-market. Expert support at every stage—prototype to commercialization.

Bone Plate, Bone Screw, and Fixation Device Testing

Our testing service verifies the mechanical integrity of bone plates, screws, and fixation devices through ASTM-standard fatigue, bending, and torsion evaluations, providing critical data for regulatory compliance and trauma reliability.

Testing of Porous Structure and Porous Coatings for Medical Devices

Element provides porous structure testing for medical devices, evaluating mechanical and metallurgical properties to support regulatory compliance, product development, and supplier validation.