Pharmaceutical Unknown Identification and Impurity Testing

Deliver safer pharmaceutical products to market faster with our comprehensive impurity testing that meets all regulatory standards. Our advanced identification services and specialized methods quickly characterize unknown compounds while maintaining full compliance with ICH guidelines and FDA requirements. Our expert analysis helps prevent development delays and streamlines your path to market approval.

What is Pharmaceutical Unknown Identification and Impurity Testing at Element?

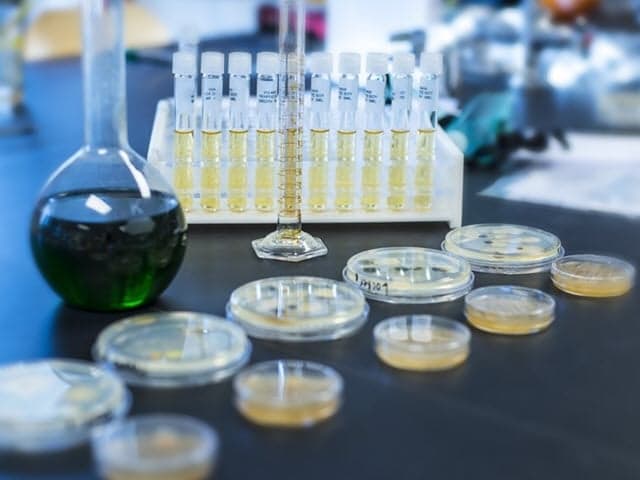

Pharmaceutical impurity testing identifies and quantifies unwanted compounds that can affect drug safety and efficacy. At Element, we provide complete impurity analysis services for both organic and inorganic materials, supporting method development and product investigations throughout your drug development process.

What Can Element Offer You For Pharmaceutical Unknown Identification and Impurity Testing?

Key tests offered

Key tests offered

We deliver complete impurity characterization through organic impurity identification, elemental impurities testing to USP <232>/<233>, residual solvents analysis to ICH Q3C, and structure elucidation of unknown peaks. Our services support your development process with specialized testing for process impurities, process aids, residual solvents, and container-closure interactions. We handle organic volatile chemicals, trace metals, and complex organic impurities with equal expertise.

- Organic impurity identification and quantification

- Elemental impurities testing

- Residual solvents analysis

- Structure elucidation services

- Forced degradation studies

- Process impurities testing

- Extractables and leachables studies

- Trace metals analysis

- Metals speciation analysis

- NDSRI Testing

Materials and products we test

Materials and products we test

We analyze drug substances, APIs, biologics, excipients, and finished products throughout the pharmaceutical development cycle. Our expertise spans organic and inorganic impurity testing, delivering comprehensive analysis that maintains product quality from development through manufacturing. Our services identify impurities from API degradation, manufacturing processes, and container-closure contact, supporting both early-stage development and commercial production.

- Drug substances and APIs

- Biologic formulations

- Finished pharmaceuticals

- Raw materials and excipients

- Container-closure systems

- Process intermediates

- Manufacturing components

Methods And Solutions Offered

Methods And Solutions Offered

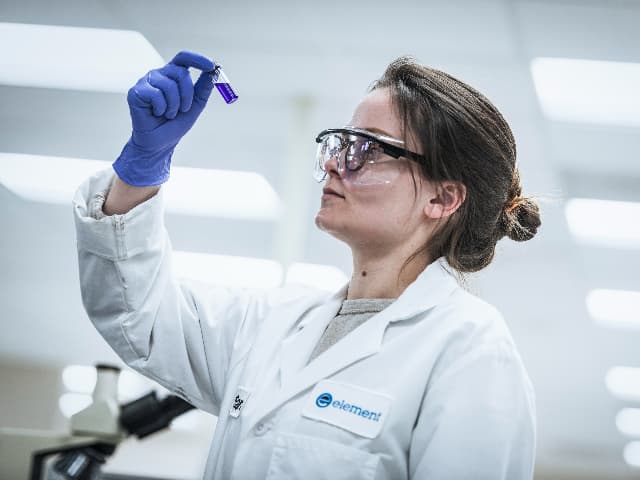

We develop and validate custom analytical methods for challenging APIs and complex matrices, including those with poor solubility and trace-level detection requirements. Our approach combines impurity isolation, characterization, and quantitative determination using advanced instrumentation aligned with industry standards. We can replicate stress conditions to reproduce unknown peaks and provide detailed structural analysis for complete impurity profiling. .

USP & ICH Impurity Profile Services:

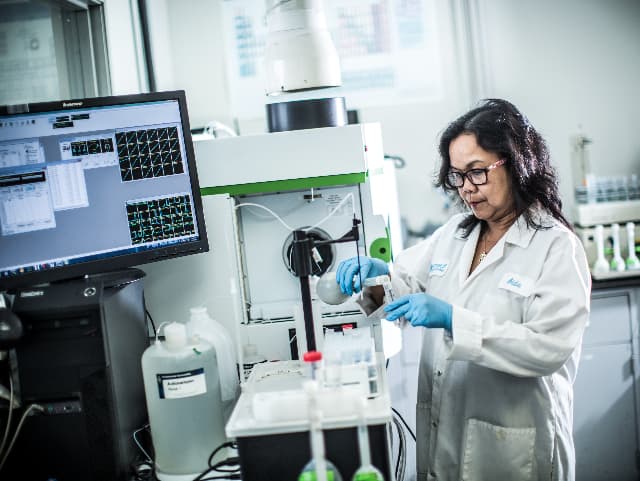

Residual solvents – These are organic volatile chemicals that remain after manufacturing processes in drug substances or excipients. They can pose patient safety risks based on toxicity and concentration. Testing follows ICH Q3C guidelines and USP <467> monograph standards.

Elemental analysis and elemental impurities – Since January 1, 2018, FDA requires all drugs to undergo elemental impurities testing to USP <232>/<233>, harmonized with ICH Q3D guidance. We specialize in developing and validating methods for challenging APIs and complex sample matrices, particularly those with poor solubility and requiring trace-level detection. Our methods include careful sample preparation techniques to ensure accurate results.

Trace metal impurities – Our comprehensive testing services cover metals speciation analysis across pharmaceuticals, biologics, medical devices, raw materials, and finished products. We develop and validate analytical methods for qualitative and quantitative limits testing of specific elements and metals, adhering to USP general chapters and monographs. Our specialized methodology distinguishes between different oxidation states and chemical forms of metals to assess toxicity accurately.

Process impurities and residuals in biologics – We develop and validate custom analytical methods for identifying and quantifying impurities in biologic drug products per ICH Q6B specifications. This includes analysis of cell substrate-derived, cell culture-derived, and downstream-derived impurities.

Organic impurity identification and quantification – We analyze impurities that arise during manufacturing or storage, including those from starting materials, intermediates, byproducts, reagents, ligands, catalysts, and degradation products. Our services span from synthesis impurity identification to stability degradation assessment. We can identify organic impurities that arise during synthesis or storage from various mechanisms, including hydrolysis, oxidation, photolysis, and other degradation pathways.

Structure elucidation – We provide rapid analysis of unknown peaks to prevent costly delays. Our laboratories can replicate stress conditions to reproduce impurity peaks, using advanced analytical instrumentation to investigate and identify unknown compounds in pharmaceuticals. We employ multiple techniques including mass spectrometry, NMR spectroscopy, and computer-aligned modeling to determine complete structures.

Extractables and leachables studies (E&L) – We examine how organic and inorganic impurities might migrate from container-closure systems, manufacturing components, process equipment, and packaging devices into finished products. Our E&L practice is among the world's largest, built on extensive regulatory knowledge and advanced equipment expertise.

Forced degradation studies and degradation products – These studies assess drug substance stability through stress testing, following ICH Q1A guidance. We offer custom method development, validation, qualitative and quantitative analysis, and comprehensive stability data tracking. We offer custom method development, validation, qualitative and quantitative analysis, and comprehensive stability data tracking. Our approach includes exposing your product to acid/base hydrolysis, oxidation, photolysis, and thermal degradation conditions to establish degradation profiles and pathways.

Which labs offer this service

Which labs offer this service

Our team operates from Life Sciences hubs across the world, providing global access to our expert capabilities. Find your nearest Life Sciences hub on our Locations Page.

Biological testing expertise

Biological testing expertise

Our dedicated teams provide specialized analysis of process impurities and residuals in biologics, following ICH Q6B specifications. We offer custom method development for product-related impurities and process residuals characterization, including cell substrate-derived, culture-derived, and downstream-derived impurities. Our comprehensive biological testing covers impurity characterization throughout the manufacturing process.

Standards we test to and materials we test

- ICH Q3A-E guidelines

- USP <1086> Impurities in Drug Substances and Drug Products

- USP <476> Organic Impurities

- USP <232>/<233> Elemental Impurities

- ICH Q3D Elemental Impurities

- FDA impurity guidance

- ICH Q6B specifications for biologics

Drug substances

- Active pharmaceutical ingredients

- Raw materials

- Intermediates

- Process aids

Drug products

- Finished pharmaceuticals

- Biologic formulations

- Drug delivery systems

Manufacturing materials

- Container closure systems

- Packaging materials

- Processing equipment

- Manufacturing materials

Your Challenges, Our Solutions

Regulatory compliance delivered seamlessly

Swift unknown compound identification achieved

Complex matrices analyzed precisely

Quality control optimized continuously

Why Choose Element

Global testing network

Regulatory knowledge leadership

Complete testing solutions

Scientific excellence

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Pharmaceutical Testing Services

Element leads the way in pharmaceutical testing services, delivering trusted expertise from prototype to analysis and finished product. With 150+ global pharmaceutical experts and 30+ years of experience.

Extractables and Leachables Testing Services

Element provides tailored extractables and leachables testing (E&L) studies to ensure patient safety and compliance with regulatory requirements.

Trace Metal Testing and Analysis Services

Element offers trace metal testing and impurity analysis services, addressing safety, compliance, and contamination challenges for pharmaceutical products with advanced techniques and global expertise.

Metals Speciation Analysis

Element offers advanced metal speciation analysis, providing detailed data on toxicity and bioavailability to support risk assessments in pharmaceuticals, biologics, and other industries.

Elemental Impurities Testing and Analysis

Industry-leading elemental impurities testing for pharmaceuticals. Offering advanced methods, accurate trace detection, and regulatory expertise to support safe and compliant drug development processes.