NDSRI Testing Regulatory Requirements, Challenges and Timelines Explained

Understanding the technical complexities and regulatory expectations for NDSRI control as manufacturers work toward compliance

The pharmaceutical industry's approach to controlling nitrosamine drug substance-related impurities (NDSRIs) continues to evolve as manufacturers navigate one of the most technically challenging impurity issues in recent regulatory history. Following FDA's quiet June 2025 adjustment to implementation timelines, many companies find themselves reassessing NDSRI testing strategies, mitigation approaches, and resource allocation to address these complex impurities.

For quality and regulatory professionals managing NDSRI programs, understanding both the scientific challenges and the regulatory landscape becomes essential to developing effective, sustainable control strategies.

The Regulatory Landscape: From August Deadline to Progress Reports

In June 2025, FDA updated its CDER Nitrosamine Impurity Acceptable Intake Limits webpage with a significant shift in expectations. While confirmatory testing remained due by August 1, 2025, the agency acknowledged that full implementation of mitigation strategies would require additional time for many approved products. Manufacturers unable to complete all necessary changes by that deadline could instead submit detailed progress reports through their annual reports.

This adjustment reflects FDA's recognition that nitrosamine mitigation strategies vary widely depending on the specific product and approach. Some manufacturers might need to reformulate products entirely, while others may add new specifications or implement enhanced process controls. Each path requires substantial development work, analytical method validation, and often complex supply chain coordination that cannot be rushed without potentially introducing new quality risks or triggering drug shortages.

The progress reports FDA now accepts must demonstrate concrete steps toward compliance. This includes confirmatory testing results showing whether NDSRIs form under targeted forced degradation conditions, descriptions of mitigation strategies under development or implementation, timelines for completing these strategies, and documentation of any interim controls established while full mitigation is underway.

FDA has indicated it will use these progress submissions to establish revised targeted timelines for different products and mitigation approaches, though the agency has not yet specified when these new deadlines will be communicated. This approach suggests FDA recognizes that one-size-fits-all deadlines may not serve patient safety or drug supply interests.

Understanding NDSRIs: Why These Impurities Present Unique Challenges

To appreciate why NDSRI control has proven so complex, it helps to understand what makes these impurities different from the nitrosamines that first captured regulatory attention.

FDA's September 2024 revised guidance (Revision 2 of "Control of Nitrosamine Impurities in Human Drugs") clearly delineates two structural classes of nitrosamine impurities. Small-molecule nitrosamines like NDMA, NDEA, NDBA, and NMPA are relatively common impurities that can arise from reagents, solvents, recovered materials, or other manufacturing components containing secondary, tertiary, or quaternary amines. While detecting and controlling these impurities presents challenges, the analytical approaches are relatively standardized, and acceptable intake limits are established.

NDSRIs, by contrast, share structural similarity to the active pharmaceutical ingredient itself. They form when vulnerable amine groups within the API structure, or in closely related intermediates and impurities, react with nitrosating agents. This structural relationship to the API means NDSRIs are typically unique to each drug substance, requiring product-specific analytical methods, risk assessments, and control strategies.

The formation pathway matters because it affects where and when NDSRIs might appear. While small-molecule nitrosamines often trace back to specific raw materials or process steps, NDSRIs can form whenever the API's inherent chemical structure creates vulnerability to nitrosation. This can occur during manufacturing, but also potentially during storage if conditions allow degradation pathways that generate both vulnerable amines and nitrosating species.

The Analytical Challenge: Detecting Impurities at Parts-Per-Billion Levels

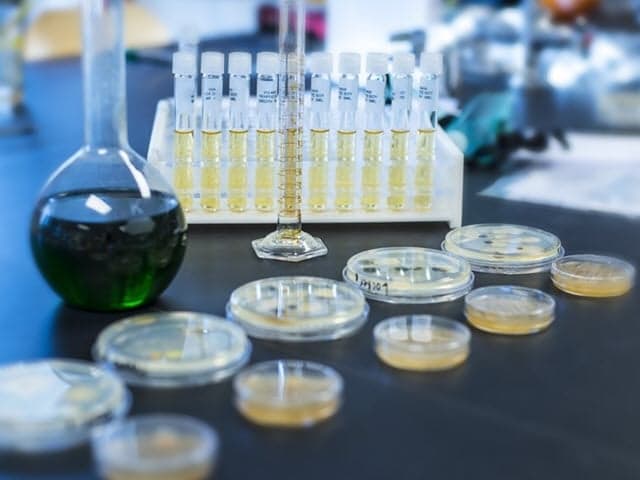

From a testing perspective, NDSRI analysis requires sophisticated analytical capabilities. These impurities must be detected and quantified at extremely low concentrations, often in the parts-per-billion range or lower, within complex matrices containing the API, excipients, degradation products, and other components.

High-performance liquid chromatography coupled with tandem mass spectrometry (LC-MS/MS) has become widely adopted for NDSRI analysis, providing the combination of sensitivity and selectivity these determinations require. However, method development for each unique NDSRI can be time-consuming, requiring optimization of extraction procedures, chromatographic conditions, and mass spectrometry parameters.

Matrix effects present a persistent challenge. The presence of high concentrations of API and excipients can suppress or enhance ionization of trace-level NDSRIs, affecting quantitation accuracy. Method validation must demonstrate that the analytical approach can reliably detect and quantify the target NDSRI in the specific product matrix, often requiring matrix-matched calibration standards or standard addition techniques.

Sample preparation adds another layer of complexity. Some NDSRIs may be thermally labile or prone to degradation during extraction, while others might have poor recovery from certain matrices. The analytical method must preserve the impurity's integrity while effectively extracting it from the sample matrix and removing interferences that could compromise detection.

For products where NDSRI formation is suspected but not confirmed, forced degradation and/or accelerated stability studies under nitrosating conditions help establish whether the API structure is truly vulnerable. These studies typically involve exposing the drug substance to nitrite under various pH and temperature conditions to determine if NDSRIs form and at what levels. The results inform both the risk assessment and the need for routine testing.

Risk Assessment: The Foundation of NDSRI Control

FDA's guidance emphasizes risk-based approaches to nitrosamine control. This begins with a thorough assessment of whether a given API and its manufacturing process present NDSRI formation risks.

The structural evaluation examines the API for vulnerable amine groups, secondary, tertiary, or quaternary amines, or amides of secondary amines, that could undergo nitrosation. Even if the parent API lacks these features, intermediates, impurities, or degradation products might contain vulnerable structures. Understanding the complete impurity profile and degradation pathways becomes essential to comprehensive risk assessment.

Process evaluation considers potential sources of nitrosating agents throughout manufacturing. While obvious sources like sodium nitrite used as a reagent demand attention, FDA guidance emphasizes that nitrite can be ubiquitous in small quantities. Raw materials, recovered solvents, equipment, and even packaging materials may introduce trace nitrite or other nitrosating agents. This ubiquity means that risk exists whenever vulnerable amines are present, regardless of whether a nitrosating agent is intentionally used in the process.

The assessment should also consider formulation and storage conditions. Some drug products may create environments where nitrosation becomes more likely: acidic pH, presence of certain excipients, humidity, or conditions that promote oxidative degradation generating nitrosating species. Long-term stability programs may need to specifically monitor for NDSRI formation over the product shelf life.

Based on this risk assessment, manufacturers determine appropriate control strategies. These might include changing raw material suppliers to avoid nitrite sources, modifying manufacturing processes to eliminate vulnerable intermediates, reformulating products to avoid problematic excipients, adding specifications to test for NDSRIs, or implementing enhanced cleaning procedures for shared equipment.

The Path Forward: Building Sustainable NDSRI Control Strategies

As the pharmaceutical industry moves beyond the August 2025 milestone, several principles emerge for effective NDSRI management.

Invest in robust analytical capabilities early. The sensitivity and specificity required for NDSRI testing means method development cannot be rushed. Organizations that invested in analytical capabilities and method validation early in their NDSRI programs have been better positioned to generate the confirmatory testing data FDA expects.

Take a lifecycle perspective. NDSRI control isn't a one-time assessment, but an ongoing program. As manufacturing sites change, raw material suppliers shift, or processes are optimized, the nitrosamine risk profile may evolve. Building monitoring into routine stability programs and change control procedures helps maintain control over time.

Document scientific rationale thoroughly. Whether justifying that NDSRIs won't form, proposing specific acceptable intake limits, or implementing particular control strategies, the quality of scientific justification matters. FDA evaluates not just what manufacturers conclude, but how they reached those conclusions and whether the supporting data are robust.

Consider supply chain implications early. Some mitigation strategies have cascading effects on supply chains. Reformulation might require new excipient suppliers. Specification changes might disqualify certain API batches. Understanding these implications before committing to a particular mitigation approach helps avoid surprises during implementation.

Maintain communication with API suppliers. For many drug product manufacturers, effective NDSRI control depends on understanding what's happening upstream in API manufacturing. Clear communication about nitrosamine risks and control measures between drug product manufacturers and their API suppliers becomes essential to comprehensive control strategies.

Where NDSRI Testing Partnerships Add Value

The technical complexity of NDSRI analysis and the resource demands of comprehensive testing programs have led many manufacturers to evaluate their testing strategies and capabilities.

Organizations with extensive in-house analytical laboratories may still face challenges when NDSRI testing requires specialized expertise, instrumentation, or method development capabilities they haven't needed to maintain for other programs. The learning curve for developing validated NDSRI methods can be steep, and building this capability from scratch may not make strategic sense for every organization.

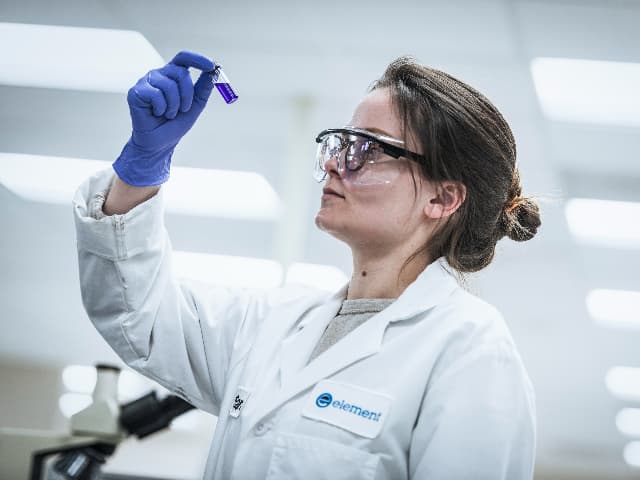

Testing laboratories with established NDSRI programs bring several advantages. Experience with method development for multiple APIs accelerates the process of creating validated, product-specific methods. Familiarity with regulatory expectations for NDSRI testing helps ensure that analytical approaches will withstand regulatory scrutiny. Access to advanced instrumentation optimized for trace-level analysis provides the sensitivity these determinations demand.

Perhaps most importantly, external testing partnerships allow pharmaceutical companies to focus internal resources on their core competencies: formulation development, process optimization, and strategic decision-making about mitigation approaches, while ensuring the analytical foundation supporting these decisions meets the highest standards.

What FDA’s Progress-Based Timelines Mean for NDSRI Testing

FDA's evolution from rigid deadlines to progress-based timelines reflects a maturing regulatory approach that balances urgency with practicality. The agency clearly expects manufacturers to treat NDSRI control as a priority, but also recognizes that effective mitigation requires time to execute properly.

For manufacturers at any stage of their NDSRI journey, from initial risk assessment through validated mitigation, the quality of analytical data directly influences both compliance timelines and confidence in product safety. As FDA reviews progress reports and establishes revised implementation expectations, the testing strategies supporting NDSRI programs will only grow more critical.

The organizations navigating this landscape most effectively aren't necessarily those with the largest budgets or biggest laboratories. They're the ones that recognized early that NDSRI control requires specialized expertise, invested in understanding their specific risks thoroughly, and built comprehensive strategies combining sound science with practical implementation approaches.

Element's nitrosamine impurity testing capabilities support pharmaceutical manufacturers at every stage of NDSRI control programs, from initial risk assessment through confirmatory testing and ongoing monitoring. Our analytical chemistry laboratories provide the specialized expertise and advanced instrumentation required for detecting and quantifying these challenging impurities.

Ready to discuss your NDSRI testing needs? Contact our analytical team.

Related Services

Extractables and Leachables Testing Services

Element provides tailored extractables and leachables testing (E&L) studies to ensure patient safety and compliance with regulatory requirements.

Stability Testing and Forced Degradation Studies for Pharmaceuticals

ICH-compliant stability storage and testing with integrated analytical services, ensuring controlled conditions from storage through analysis in FDA-registered facilities supporting pharmaceutical development programs.

Analytical Method Development & Validation

Element's regulatory and industry experts have a proven track record of successfully developing and validating fit-for-purpose, accurate, and reliable analytical methods based on established CDER/ICH and FDA guidelines and procedures.

Pharmaceutical Unknown Identification and Impurity Testing

Element offers expert impurity testing services for pharmaceuticals, ensuring drug safety, quality, and compliance with FDA and ICH guidelines through advanced analytical methods and tailored solutions.

Pharmaceutical Testing Services

Element leads the way in pharmaceutical testing services, delivering trusted expertise from prototype to analysis and finished product. With 150+ global pharmaceutical experts and 30+ years of experience.