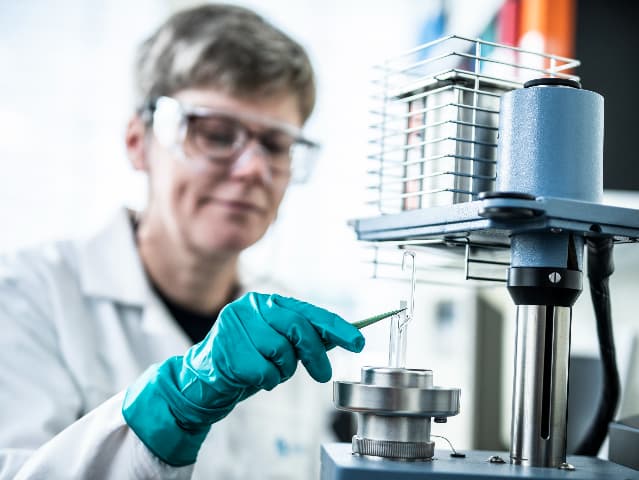

Thermogravimetric Analysis (TGA) Services

Unlock critical insights into your materials' thermal behavior with precise analysis that reveals composition, stability, and performance characteristics. Element's comprehensive TGA testing delivers detailed data across a wide range of heating rates and reactive atmospheres, with expert interpretation of results to optimize your material development and ensure quality control.

What is Thermogravimetric Analysis (TGA) at Element?

Thermogravimetric analysis is a thermal analysis method that measures changes in material mass as a function of temperature and time. At Element, we provide advanced TGA testing services to analyze phase transitions, evaluate degradation reactions, and determine key polymer properties, delivering precise insights into material behavior and characteristics.

What Can Element Offer You For Thermogravimetric Analysis (TGA) Services?

Key tests offered

Key tests offered

We deliver detailed analysis of thermal stability, compositional makeup, moisture content, and volatile components. Our testing reveals critical phase transitions and material degradation characteristics, supporting both research and quality control requirements. Our capabilities include:

- Compositional analysis of multi-component materials

- Thermal stability evaluations

- Moisture and volatiles content determination

- Reactive atmosphere testing

- Hidden transition identification

Materials we test

Materials we test

Our comprehensive TGA testing capabilities cover a wide range of non-metallic materials, with particular expertise in polymers and multi-component blends. We analyze materials for research, development, and production applications, providing detailed insights into thermal behavior and stability characteristics.

- Polymer materials and blends

- Advanced non-metallic materials

- Multi-component materials

- Research and development materials

- Production materials

Methods and solutions offered

Methods and solutions offered

Our TGA services utilize precise heating protocols up to 1,100°C across various heating rates. In thermogravimetric analysis, a small sample is gradually heated to a set temperature while its weight is continuously monitored. Any changes in mass are recorded throughout the process. After the analysis, our experts carefully examine the resulting graph, identifying key transition points and structural changes. These insights help us determine the material’s fundamental properties. We analyze mass changes under controlled conditions, providing detailed data on material composition, stability, and behavior under different atmospheric conditions.

As part of our comprehensive thermal analysis capabilities, we offer:

- Thermogravimetric analysis (TGA)

- Differential Scanning Calorimetry (DSC)

- Dynamic Mechanical Analysis (DMA)

- Thermomechanical Analysis (TMA)

- Heat Deflection Temperature testing

- Linear Thermal Expansion analysis

Cutting-edge equipment we use

Cutting-edge equipment we use

Our advanced TGA/DSC systems enable high-precision measurements up to 1,100°C, offering exceptional temperature control and weight measurement accuracy.

The equipment supports various atmospheric conditions for comprehensive material analysis and delivers precise data for both research and quality control applications.

Standards we test to and materials we test

- ASTM D3850

- ASTM D6370

- ASTM D6375

- ASTM E1131

- ASTM E1641

- Multi-component materials and blends

- Polymers

- Advanced materials

Your Challenges, Our Solutions

Understanding complex material interactions

Optimizing material performance

Material stability validation

Complex, unclear quality assurance process

Why Choose Element

Global expertise

Comprehensive solutions

Industry leadership

Lifecycle support

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Energy Coatings Testing Services

Protect your critical energy assets with Element's specialized coatings testing. We simulate extreme offshore and pipeline conditions to validate performance, prevent costly failures, and ensure compliance. Learn More.

Polymer Testing & Characterization Services

Maximize your polymer material performance with Element's comprehensive testing services. Our expert analysis translates complex data into actionable insights across your entire product lifecycle.

Thermogravimetric Analysis (TGA) Services

Element's thermogravimetric analysis (TGA) services help identify phase transitions, degradation reactions, and material composition, providing critical insights for research, development, and compliance across industries.

Thermomechanical Analysis (TMA)

Thermomechanical analysis (TMA) evaluates polymer thermal properties, including expansion and phase changes. Element provides precise data for R&D, quality control, and material classification.

Differential Scanning Calorimetry (DSC) Analysis Services

Element's Differential Scanning Calorimetry (DSC) analysis measures material properties, helping you optimize designs and ensure performance with accurate thermal data for informed decision-making in product development.

Thermal Analysis Services

Element's thermal analysis services help identify material properties, anticipate changes, and reduce failure risks. Our experts provide accurate, reliable testing for polymers, composites, and advanced materials.