Nuclear Systems and Component Testing Services

Element is your single partner for nuclear systems and component testing, supporting safety, compliance, and performance throughout your facility's entire lifecycle. From new build qualification to life extension assessments and plant outage services, our comprehensive capabilities can meet your challenges. Whether it is equipment qualification and dedication of equipment, aging analysis, material testing or valve, snubber, and inspection services we can help you meet regulatory requirements while maintaining operational excellence.

What are Nuclear Systems and Component Testing Services at Element?

Nuclear systems and component testing encompasses the critical examination and verification of materials, components, and systems used in nuclear facilities to ensure safety, performance, and regulatory compliance during a service life. At Element, we provide comprehensive and customized testing capabilities across the entire nuclear lifecycle—from initial design and construction through operation. We solve operational, obsolescence and life extension challenges by compliance with customer specifications and industry standards overseen by a Nuclear Quality Assurance program audited by NIAC, NUPIC and other organizations.

What Can Element Offer You For Nuclear Systems and Component Testing?

Key tests offered

Key tests offered

Element delivers comprehensive mechanical testing, non-destructive testing (NDT), weld testing services, fracture toughness testing, corrosion testing, and coatings testing. Our Nuclear Equipment Qualification (EQ) Services verify that your components perform their required functions throughout their operational lives, even under accident or seismic conditions, helping you maintain regulatory compliance and operational safety. These qualification processes are essential for nuclear power stations, ensuring long-term reliability while meeting regulatory requirements.

- Mechanical testing for structural integrity

- Non-destructive testing for flaw detection

- Weld testing and procedure qualification

- Fracture toughness assessment

- Corrosion resistance evaluation

- Coatings performance testing

- Equipment qualification under accident conditions

- Seismic qualification testing

- Modal analysis and testing

- Fixture design and fabrication

Components and materials we test

Components and materials we test

From critical reactor components to balance of plant systems, we test the full spectrum of nuclear facility materials and components. We provide qualified replacements from over 200 manufacturers including Bussman, Siemens, Yokogawa, and GE, with technical evaluations, critical characteristics verification, and safety class determinations for each product. We specialize in testing, inspection and analysis of materials used in all stages of nuclear power generation, from new construction to ongoing operations and decommissioning projects.

- Digital assets for control room and plant use

- Metallic and non-metallic component materials

- Harsh and mild environment equipment

Methods and solutions offered

Methods and solutions offered

Our solutions span the complete nuclear facility lifecycle, from new build quality assurance to life extension assessments and decommissioning support. We conduct Fitness For Service (FFS) testing and Engineering Critical Assessment (ECA) to maintain structural integrity while minimizing risks. For decommissioning, we provide materials testing, integrity verification, and environmental compliance, including asbestos remediation and air quality monitoring. Our comprehensive approach helps you minimize operational risks, prevent production losses, and avoid severe environmental impacts throughout your facility's lifecycle.

- New build quality assurance from design to commissioning

- Fitness For Service (FFS) assessments for operational assets

- Engineering Critical Assessment (ECA) for structural integrity

- Life extension evaluations for aging facilities

- Decommissioning support with environmental compliance

- Asbestos remediation works during site decommissioning

- Management surveys and project management

Regulatory and environmental compliance

Our environmental experts in the UK provide crucial support for your regulatory compliance needs, including workplace air monitoring, electromagnetic field surveys, asbestos testing, and occupational hygiene services. All operations align with national legislation like CAR 2012 and international standards ISO/IEC 17025 and ISO/IEC 17020, helping you maintain environmental safety throughout facility operation and decommissioning. We help you navigate complex regulatory frameworks while ensuring your facility maintains the highest levels of environmental protection and worker safety.

- Workplace air quality monitoring and assessment

- Electromagnetic field surveys and radiation protection

- Comprehensive asbestos management services

- Asbestos air testing and removal project management

- Occupational hygiene evaluations

- Environmental compliance auditing

- Refurbishment and demolition environmental surveys

- Regulatory documentation and reporting support

Cutting-edge equipment we use

Cutting-edge equipment we use

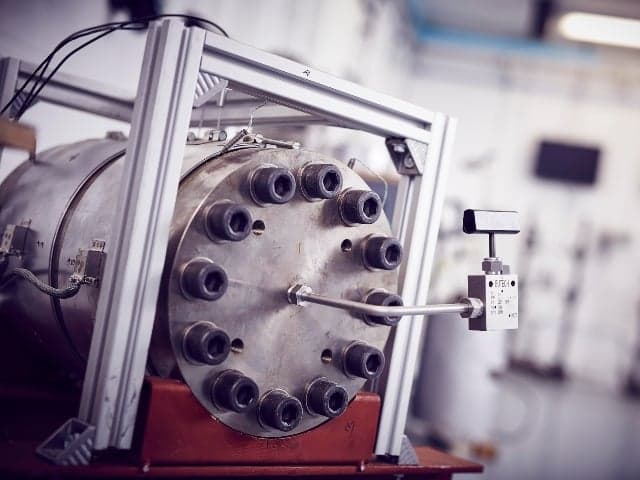

Our Digital Engineering team utilizes advanced modeling and simulation software to calculate safety and efficiency of critical components during design and development. We apply thermal hydraulics simulation for primary, secondary, and tertiary circuits, while our integrity specialists leverage nuclear integrity codes including R5, R6, and ASME design standards to deliver comprehensive component assessments. These digital capabilities allow us to identify potential issues early in the development process, reducing costs and enhancing safety before physical components are manufactured or installed. For physical testing, we utilize three single axis, triaxial and biaxial seismic machines for quick response to your needs.

- Advanced modeling and simulation software

- Thermal hydraulics simulation technologies

- Non-destructive testing equipment for in-service inspection

- Specialized tools for mechanical and fracture toughness testing

- Corrosion testing apparatus

- Coatings performance assessment equipment

- Air monitoring and environmental testing instrumentation

- Seismic qualification testing systems

- More than 30 different aging ovens for environmental qualification with temperatures continuously recorded and maintained within +5/-0°F using redundant controllers to prevent overheating

- Eight permanent test chambers using saturated and superheated steam, water and chemical spray availability for LOCA and submergence testing

Which labs offer this service

Which labs offer this service

Our Huntsville, AL Nuclear Center of Excellence lab is IEEE ICAP certified and radioactive material licensed with a compliant NUPIC and NIAC audited Nuclear QA program. In the UK, we are part of the Equipment Qualification Services Alliance (EQSA), helping UK manufacturers trade in the nuclear industry. As members and direct participants in industry task groups, Element maintains a clear edge by actively developing standards, guidelines and resolution of key NRC questions about critical characteristics verification, sampling, traceability, surveys, and like-for-like replacements.

Standards we test to and products we test

- R5 and R6 nuclear integrity codes

- ASME nuclear design codes

- CAR 2012

- ISO/IEC 17025

- ISO/IEC 17020

- IEEE 323 and IEEE 344

- ANSI N45.2.6 Level II Inspector requirements

- EPRI NP-5652 Nuclear Dedication

Nuclear facility infrastructure

- Safety Relief Valves and Snubbers

- Digital assets for control room and plant use

- Metallic and non-metallic component materials

- Harsh and mild environment equipment

- Welded and machined parts

Waste management equipment

- Nuclear waste containment structures

- Decommissioning equipment

Digital Upgrade Systems:

- Safety-related system replacements

- Instrumentation panel and component designs

- EMI surveys

Your Challenges, Our Solutions

Meeting stringent safety requirements

Aging facility integrity challenges

Complex decommissioning

Meeting environmental standards

Why Choose Element

Complete lifecycle support

World-class materials expertise

Digital simulation capabilities

Global reach, local support

Frequently asked questions

How does Element support new nuclear power plant development?

Our experts provide quality assurance from initial design through construction to commissioning. We deliver Nuclear Equipment Qualification, comprehensive materials testing, and Digital Engineering services with advanced modeling to ensure your new facility meets all safety and regulatory requirements.

What specialized engineering services do you offer for older plants?

We lead the industry in digital upgrades and provide retrofit qualification and testing, qualification assessment and upgrades, equivalency testing for replacement parts, predictive maintenance programs, plant life extension (PLEX) consulting, commercial grade dedication, materials aging database services, and seismic analyses and upgrades

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Asset Integrity Management (AIM) Services

Element's Asset Integrity Management services ensure energy assets remain reliable and safe throughout their lifecycle. From testing to preventive maintenance, we help energy and petrochemical companies minimize costs, extend asset lifespan, and maintain regulatory compliance.

Carbon Capture and Storage (CCS) Testing

Testing services related to the corrosion issues of Carbon Capture, Utilization and Storage (CCS/CCUS). We help manage challenges with polymeric materials and composites in service in supercritical CO2 (scCO2) environments.

Fitness for Service (FFS) Assessments

Element's Fitness for Service assessments ensure equipment safety, minimize risks, and prevent costly failures. We deliver reliable evaluations to help you make informed run-repair-replace decisions across your equipment's lifecycle.

Oil and Gas Corrosion Testing Services

Element's oil and gas corrosion testing identifies material vulnerabilities, supports compliance, and prevents failures through advanced simulation, predictive modeling, and testing in extreme environments.

Nuclear Testing

Leading nuclear testing and safety-related engineering services for utilities and manufacturers. Expert equipment qualification, valve testing, and regulatory compliance. Learn More

Nuclear Equipment Qualification Services

Ensure your nuclear equipment meets safety, efficiency, and regulatory standards with Element's expert Nuclear Equipment Qualification Services.

Environmental Impact Assessments Services

Element's Environmental Impact Assessments provide air, noise, and vibration studies to meet planning and regulatory needs. Backed by advanced modeling and independent verification, we deliver accurate results to protect communities, ensure compliance, and streamline your project planning.

Non-Destructive Testing (NDT) and Inspection Services

Get precise, reliable non-destructive testing (NDT) to detect flaws, verify material integrity, and meet industry standards, saving time and reducing risk. View services.

Fracture Mechanics and Fracture Toughness Testing

Element provides fracture mechanics and fracture toughness testing services to evaluate material resistance, reduce repair costs, and optimize designs for safer, longer-lasting components across industries.